Popular searched products:

Product Description

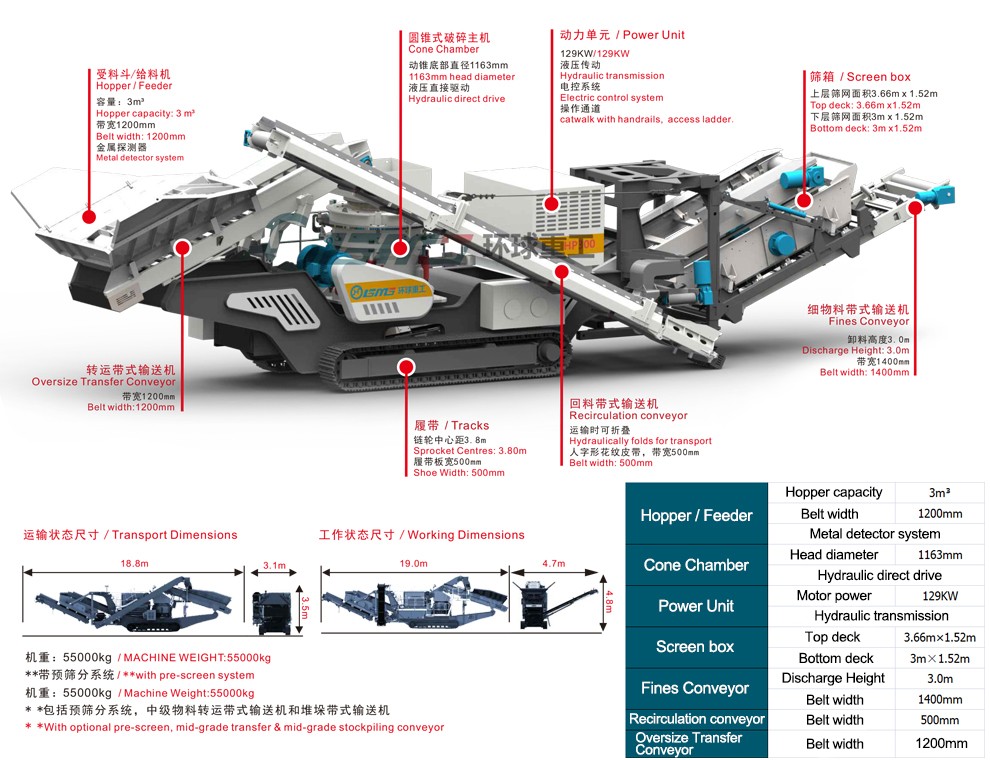

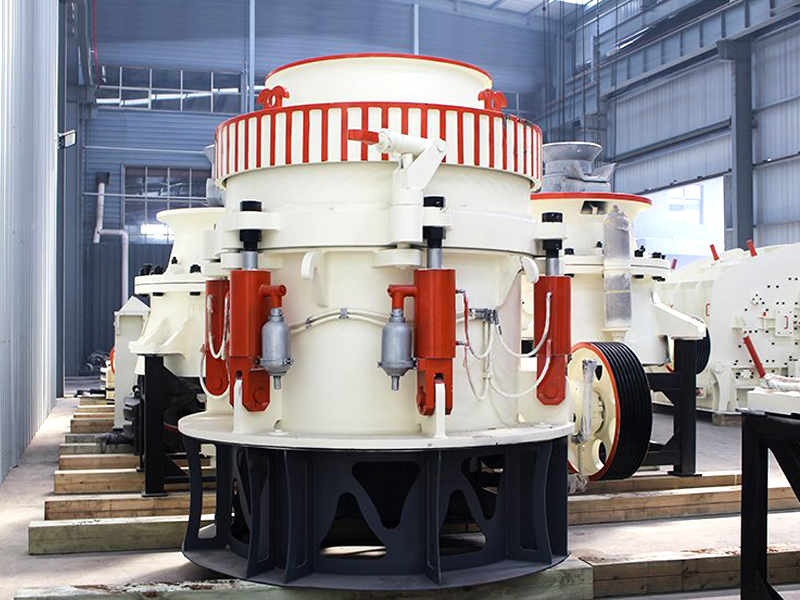

HCR tracked mobile cone crusher provides the versatility of a crushing and screening plant on one machine in aggregate and ore surface mining applications. Based on the proven and tested HCR cone crusher, this machine variant features an innovative onboard recirculating system and detachable sizing screen. If recirculation and sizing of materials is not required the sizing screen can be quickly detached from the machine without the need for lifting equipment. HCR can be fitted with an optional patented pre-screen module which allows fines materials to be removed prior to being fed to the crushing chamber offering higher production with lowest cost per ton wear and running costs. The large hopper/feeder has an automated metal detection and a purge system to protect the cone and reduce downtime by removing metal contaminants from the feed belt.

Product Performance

Detachable 3.66mx 1.52m double deck sizing screen passes oversize material back to the crusher via the onboard recirculating conveyor.

Quick and easy detachable screen and fines conveyor for open circuit crushing.

The optional stacking conveyor in conjunction with the optional lower deck screen, produces a 2nd spec' d product.

Working Principle

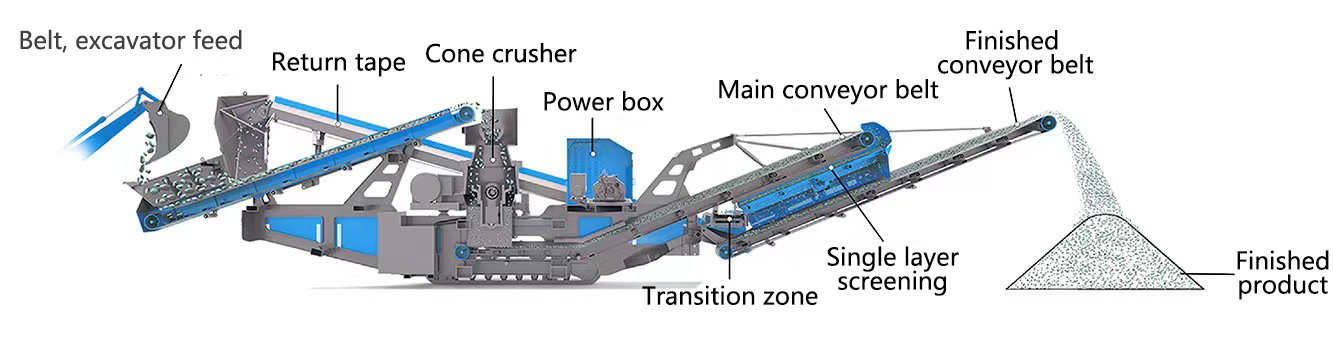

The material is uniformly transported to the cone crusher by the feeder. After the cone crusher is preliminatively broken, the closed circuit system is formed by the circular vibrating screen to realize the circulating crushing of the material. The finished material is output by the conveyor for continuous crushing operation. The track cone breaking + vibrating screen mobile crushing station can remove the circular vibrating screen according to the actual production needs, and realize the preliminary crushing of materials directly. It is convenient and flexible to use with other crushing equipment.

Technical Parameters

| HC300R | HC400R |

|---|---|

| Hopper Feeder | |

| Hopper capacity: 3m³, with impact reducing cross bars | Hopper capacity: 3m³, with impact reducing cross bars |

| Hydraulic retraction system (foldable for transport) | Hydraulic retraction system (foldable for transport) |

| Heavy duty large torque hydraulic drive feed conveyor | Heavy duty large torque hydraulic drive feed conveyor |

| Belt width: 1200mm | Belt width: 1200mm |

| Feeder fitted with metal detector with auto-stop | Feeder fitted with metal detector with auto-stop |

| Metal contaminants purge system | Metal contaminants purge system |

| Wear resistant liner plates (10mm) fitted to feed-in end of hopper | Wear resistant liner plates (10mm) fitted to feed-in end of hopper |

| Cone | |

| HC300 Cone chamber, Head diameter: 1163mm | HC400 Cone chamber, Head diameter: 1366mm |

| hydrostatic cone drive,electric control speed | hydrostatic cone drive,electric control speed |

| Hydraulically adjustable closed size with monitoring system | Hydraulically adjustable closed size with monitoring system |

| Mantle and concave wear indicator | Mantle and concave wear indicator |

| Tramp metal relief system with automatic reset | Tramp metal relief system with automatic reset |

| Main Conveyor | |

| Belt width: 1200mm | Belt width: 1200mm |

| High spec scraper at head drum | High spec scraper at head drum |

| Re-Circulating System | |

| Two deck screen: 3.66m x 1.52m | Two deck screen: 3.66m x 1.52m |

| Top deck mesh fitted to screen - 40mm aperture fitted unless specified otherwise | Top deck mesh fitted to screen - 40mm aperture fitted unless specified otherwise |

| Oversize transfer conveyor, re-circulating conveyor and fines conveyor fitted as standard | Oversize transfer conveyor, re-circulating conveyor and fines conveyor fitted as standard |

| Quick detach screen and fines conveyor | Quick detach screen and fines conveyor |

| Note: Standard with no intermediate material steering belt conveyor, optional | Note: Standard with no intermediate material steering belt conveyor, optional |

| General | |

| Galvanised catwalk c/w handrail, kick board and access ladders | Galvanised catwalk c/w handrail, kick board and access ladders |

| Heavy duty track unit, sprocket centres 3.8m, pad width 500 mm | Heavy duty track unit, sprocket centres 3.8m, pad width 500 mm |

| Hand held track control set with 5m connection lead | Hand held track control set with 5m connection lead |

| Single speed tracking with soft start | Single speed tracking with soft start |

| Piped for dust suppression c/w spraybars | Piped for dust suppression c/w spraybars |

| Low level greasing points | Low level greasing points |

| Two auxiliary drive | Two auxiliary drive |

| Emergency stops (7nr) | Emergency stops (7nr) |

| High specification oil cooler | High specification oil cooler |