Popular searched products:

Product Description

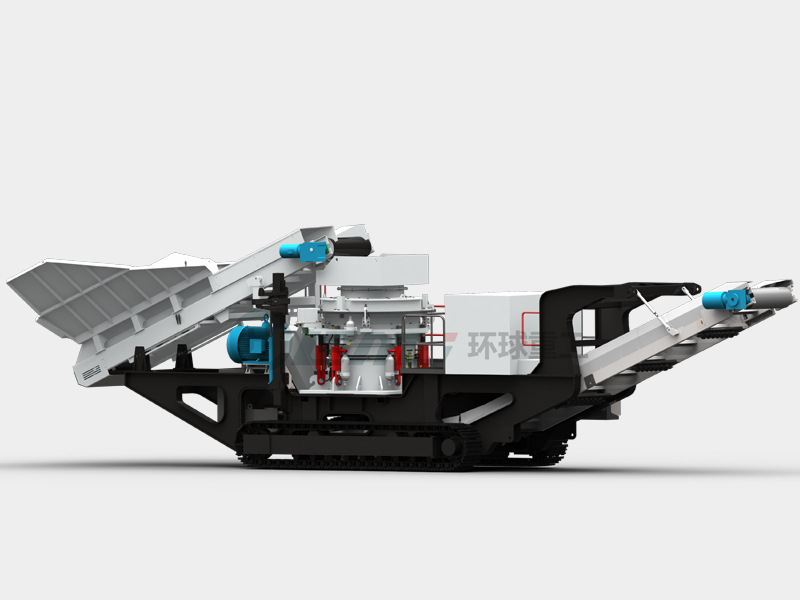

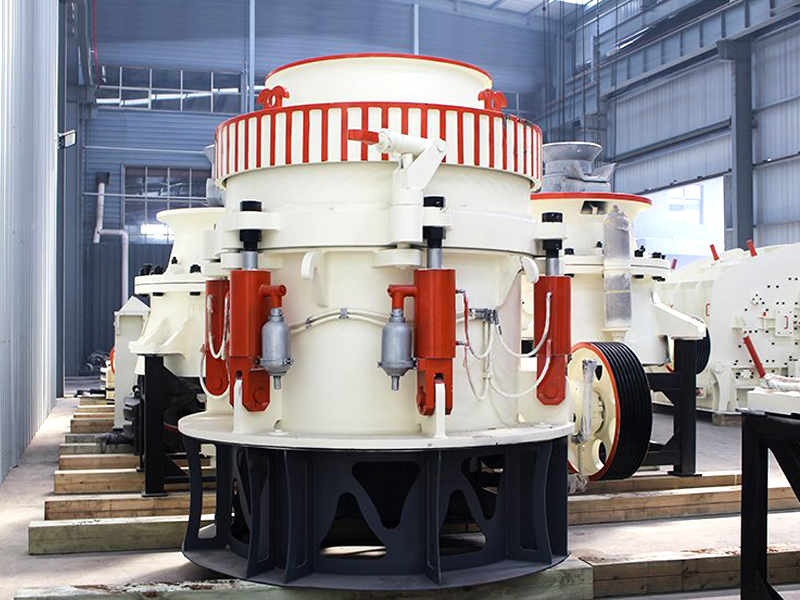

HC is an efficient and productive machine incorporates the proven HC300 cone crusher with direct variable clutch drive, automatic tramp relief and hydraulic closed side setting (CSS) adjustment. The large hopper/feeder has an automated metal detection and a purge system to protect the cone and reduce downtime by removing metal contaminants via the purge chute. Additional benefits include rapid set up time, ease of maintenance, high reduction ratio, high output capacity and advanced electronic control system

Product Performance

Fully Hydraulic CSS Adjustment with electronic monitoring system ensures ease of operation.

Direct hydrostatic cone drive with variable speed control gives efficient production and application versatility.

Hydraulic Tramp Relief System with automatic reset protects the chamber and minimises downtime.

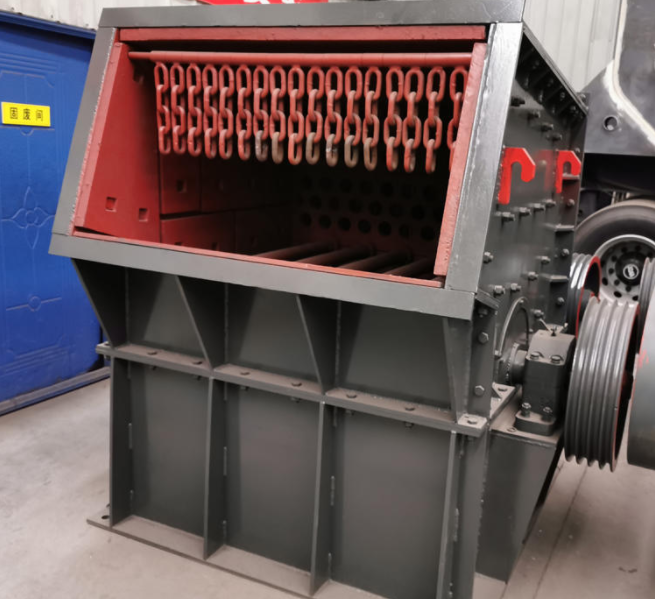

Metal detection system on feed belt with 'auto-stop' protects the cone from tramp metal and the purge system removes contaminants from the machine.

Working Principle

The material is uniformly transported to the cone crusher by the feeder. After the cone crusher is preliminatively broken, the closed circuit system is formed by the circular vibrating screen to realize the circulating crushing of the material. The finished material is output by the conveyor for continuous crushing operation. The track cone breaking + vibrating screen mobile crushing station can remove the circular vibrating screen according to the actual production needs, and realize the preliminary crushing of materials directly. It is convenient and flexible to use with other crushing equipment.

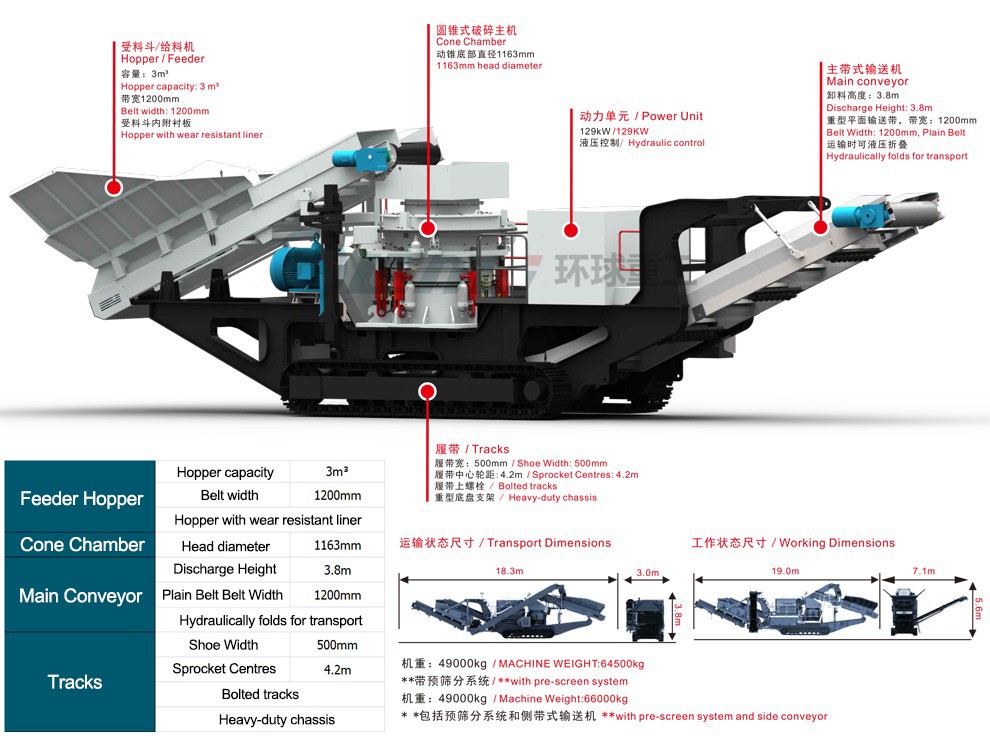

Technical Parameters

| HC300 | HC400 |

|---|---|

| Hopper Feeder | |

| Hopper capacity: 3m³, with impact reducing cross bars | Hopper capacity: 3m³, with impact reducing cross bars |

| Belt width: 1200mm | Belt width: 1200mm |

| Low level drop down rear feed point | Low level drop down rear feed point |

| Hydraulic retraction system (foldable for transport) | Hydraulic retraction system (foldable for transport) |

| Controllable discharge system to purge metal contaminants from belt | Controllable discharge system to purge metal contaminants from belt |

| Heavy duty large torque hydraulic drive feed conveyor | Heavy duty large torque hydraulic drive feed conveyor |

| Wear resistant liner plates 20mm fitted to feed in end of hopper | Wear resistant liner plates 20mm fitted to feed in end of hopper |

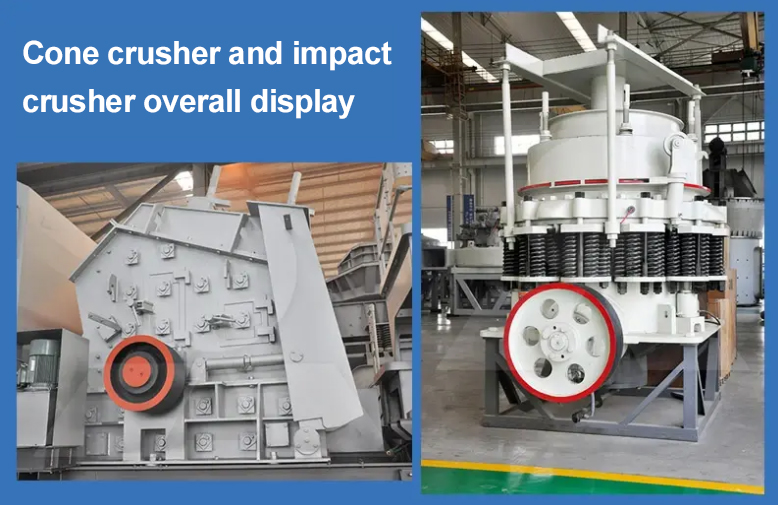

| Cone | |

| HC300 cone chamber, 1163 mm head diameter | HC400 cone chamber, 1366 mm head diameter |

| Medium coarse concave (max feed size 200mm) | Medium coarse concave (max feed size 200mm) |

| Direct drive cone via drive shaft and feeder belt | Direct drive cone via drive shaft and feeder belt |

| On the fly" hydraulically adjustable closed size with monitoring system | On the fly" hydraulically adjustable closed size with monitoring system |

| Mantle and concave wear indicator | Mantle and concave wear indicator |

| Main Conveyor | |

| Belt width: 1200mm | Belt width: 1200mm |

| High spec scraper at head drum | High spec scraper at head drum |

| Wear resistant liners(16mm) at crusher discharge point | Wear resistant liners(16mm) at crusher discharge point |

| With dust cover | With dust cover |

| General | |

| Galvanised catwalk c/w handrail, kick board and access ladders | Galvanised catwalk c/w handrail, kick board and access ladders |

| Heavy duty track unit, sprocket centres 4.2m, pad width 500 mm | Heavy duty track unit, sprocket centres 4.2m, pad width 500 mm |

| Hand held track control set with 5m connection lead | Hand held track control set with 5m connection lead |

| Caterpillar monolateral soft start | Caterpillar monolateral soft start |

| Piped for dust suppression c/w spraybars | Piped for dust suppression c/w spraybars |

| Low level greasing points | Low level greasing points |

| Two auxiliary drive | Two auxiliary drive |

| Piped for dust suppression c/w spraybars | Piped for dust suppression c/w spraybars |

| Emergency stops (3nr) | Emergency stops (3nr) |

| Safety guards in compliance to Machinery Directive | Safety guards in compliance to Machinery Directive |