Popular searched products:

In the production line, we commonly use jaw crushers, cone crushers or impact crushers and sand making machines. So there is a question, why choose cone crusher or impact crusher? What are cone crushers and impact crushers? Is there any difference? Everyone must be troubled by this problem. When to choose a cone crusher? When to choose an impact crusher? Today we will reveal the answer.

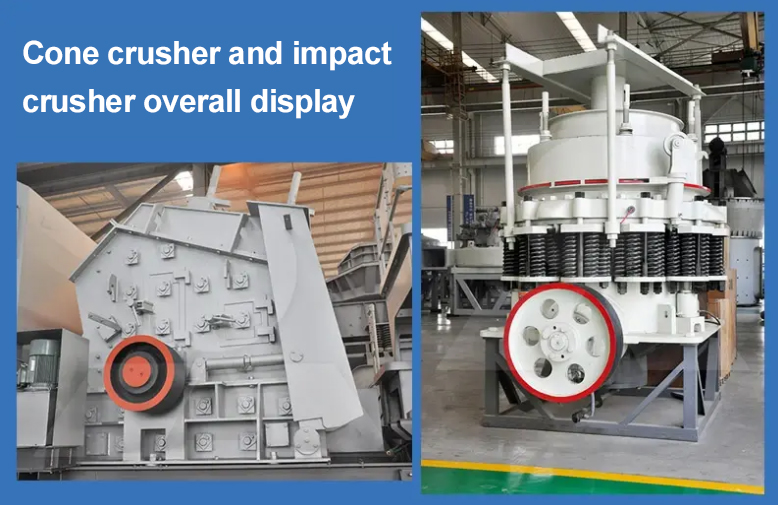

Impact crusher, referred to as impact crusher, is a commonly used equipment in sand making production lines. It is generally used as fine crushing equipment. In the crushing process, it is generally used as secondary crushing or tertiary crushing. The impact crusher adopts the impact crushing principle. The material is repeatedly impacted and broken between the blow hammer and the impact plate, and the wear rate of wearing parts is high. It focuses on crushing softer materials, such as coal gangue, river pebbles, construction waste, iron ore, quartz stone, limestone, etc. It is generally used in small and medium-sized stone factories with strict emission requirements for building materials, construction, and sand and gravel aggregates. The purchase cost of impact crusher is low, but components such as impact plate and hammer head are easy to wear and need to be replaced frequently. Later maintenance costs are relatively high.

Cone crusher, referred to as cone crusher, adopts the principle of extrusion crushing. The rolling mortar wall moves like a crushing wall, squeezing the material for crushing. It is mainly used to crush hard materials, such as granite, calcite, iron ore, limestone, bluestone, river pebbles, glass, basalt, dolomite, etc. It is generally used in large stone factories with low discharge requirements and relatively large output. The cost of the cone crusher is relatively high, but the wearing parts have a long service life, which can save subsequent maintenance costs and is cost-effective.

How to choose between cone breaking and counterattack breaking

Both devices have their own advantages and disadvantages, so choose one according to the actual situation.

Why is it sometimes necessary to use an impact crusher on the production line and sometimes not? Sometimes a cone crusher and an impact crusher are required, and sometimes separate equipment is used. It all depends on the characteristics of both devices. Let's start with functionality. The impact crusher is suitable for soft rock and has good discharge particle size; the cone crusher is suitable for hard rock and has a large output but average discharge. Therefore, when used alone, the choice should be based on the characteristics of the two devices. So when will these two pieces of equipment be used? That is, after using the cone crusher, the impact crusher is used for crushing. This is because there are requirements for the particle size of the finished product. Using an impact crusher, the discharge effect will be better. In this case, both types of equipment are used simultaneously on the same production line.

Related Reading

- Operation plan of mud treatment system in sand washing field

- These advantages make the sand washing machine the preferred equipment in the sand washing industry!

- I heard that the profit of machine-made sand washing is good, how much is it? Which equipment is suitable for machine-made sand washing?

- If you want to choose a cost-effective truck-mounted mobile sand washing machine, Zhengzhou Global Heavy Industry is your first choice

Product show

Product

Source:

Source: Time:2024/05/09 16:02:42

Time:2024/05/09 16:02:42