Popular searched products:

Product Description

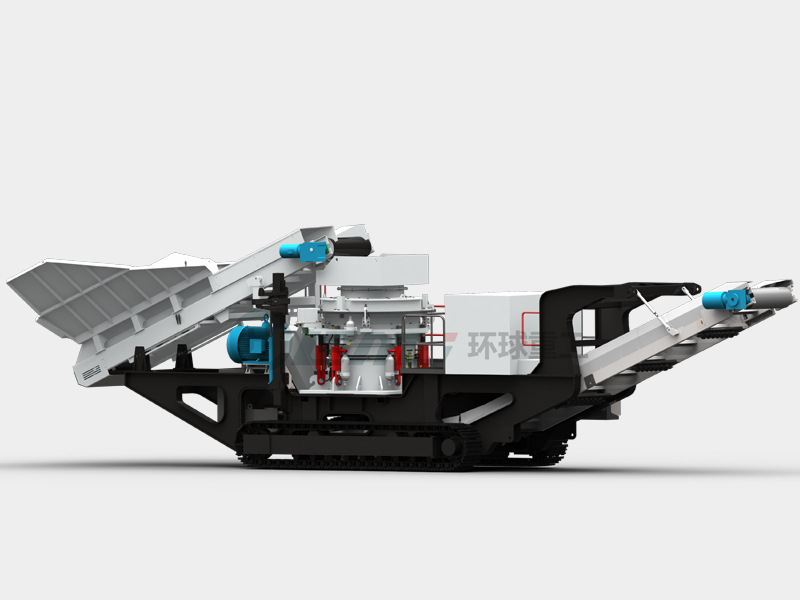

The structural design is compact, space-saving and reduces the floor space of the construction site.

The foundation treatment is simple and the equipment foundation is small, avoiding the difficulties of civil construction.

All modules are pre-tested and assembled in the factory, shortening the on-site installation time.

The equipment process is coordinated and smooth, the selection and matching degree is high, and the operating efficiency is excellent.

The installation and maintenance of the equipment are convenient, fast, safe and efficient.

The modular station is easy to disassemble and reinstall, ensuring that the project can be quickly relocated and reassembled according to construction needs. All standard modules can be loaded into standard containers for sea transportation.

Product Performance

1. The impact crusher module station is mainly used for medium crushing of minerals and rocks with a hardness below medium. 2. The structural design of the module station is simple and beautiful, and all independent components can be disassembled, which is convenient for assembly, disassembly and transportation. 3. The impact crusher module station can be equipped with standardized self-lined anti-wear inlet and outlet hoppers according to customer needs. 4. The impact crusher module station is equipped with ladders, handrails and wrap-around walkways to facilitate inspection and maintenance of various parts of the impact crusher. The integrated modular crushing and screening station is a diversified system solution that integrates one or more crushing and screening unit modules according to project requirements.Working Principle

The working principle of the impact crusher is to achieve material crushing through high-speed impact and repeated impact. Driven by the motor, the rotor rotates at high speed. When the material enters the plate hammer action area, it collides with the plate hammer on the rotor, and then is thrown to the impact device for secondary crushing, and finally rebounds from the impact liner back to the plate hammer action area for further crushing. This process is cyclical, and the material is gradually crushed in the first, second, and third impact chambers until it reaches the required particle size and is discharged from the discharge port. The impact crusher consists of main components such as the rotor, plate hammer and impact liner. During the working process, the stone falls directly from the top of the machine into the high-speed rotating turntable. With the help of high-speed centrifugal force, it collides with the surrounding umbrella-shaped flying stones at high speed to form high-density crushing. The crushed material is counterattacked to the liner again for secondary crushing. The stone forms a vortex motion between the turntable and the casing, resulting in multiple mutual impacts, friction and crushing, and finally discharged through the discharge port. By adjusting the gap between the impact frame and the rotor, the material's discharge particle size and shape can be flexibly changed to meet different processing requirements.Technical Parameters

|

Model |

MF-1110 |

MF-1310 |

MF-1315 |

MF-1320 |

MF-1520 |

|

Max Feed Size(mm) |

400 |

500 |

600 |

600 |

800 |

|

Production Capacity(t/h) |

60-100 |

100-180 |

200-280 |

280-350 |

420-500 |

|

Equipment selection |

PFQ1110 |

PFQ1310 |

PFQ1315 |

PFQ1320 |

PFQ1520 |

|

功率(kw) |

110 |

160 |

250 |

2*200 |

2*250 |

|

Main module structure |

Equipment support, maintenance platform, ladder railing, inlet and outlet hopper (optional). |

||||