Popular searched products:

Product Description

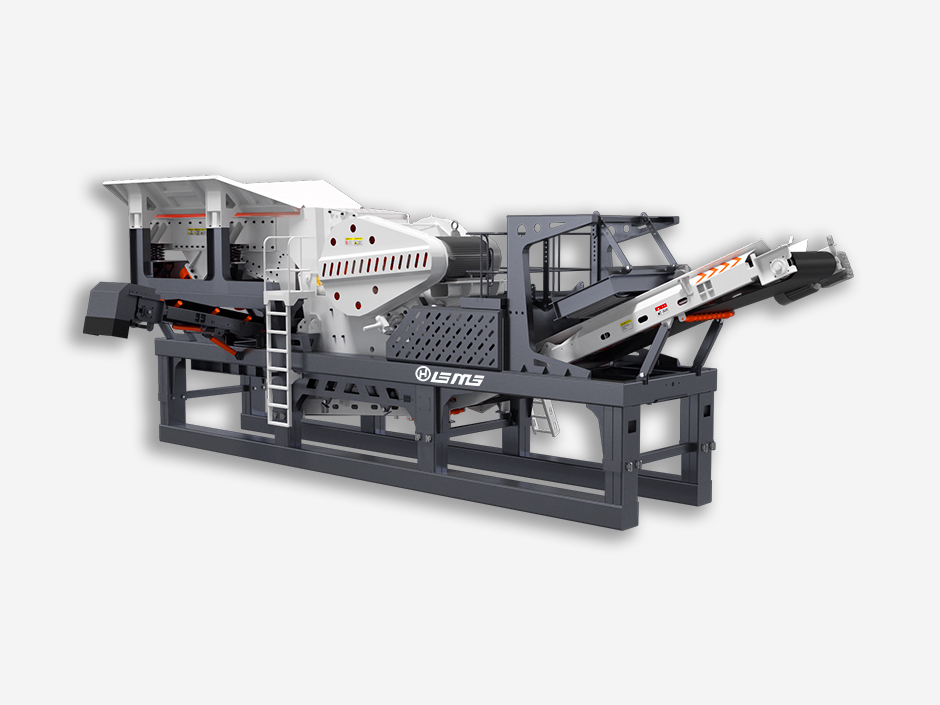

The jaw crusher modular station is mainly used for the preliminary crushing of ore and rock.

According to different production capacity requirements, various specifications of feeders, jaw crushers, belt conveyors and modular structural parts are designed.

According to different feeding methods, the modular station is designed with corresponding feeding bins to facilitate feeding with excavators or dump trucks.

According to needs, the modular station can also be equipped with a machine mouth breaker to handle oversized diameter materials, thereby improving the working efficiency of the jaw crusher.

A vibrating feeder with one or two bars is configured under the raw material bin to pre-screen and remove impurities from the raw materials.

The modular design of walkways, handrails, ladders, equipment bases, and platforms facilitates equipment installation, observation, testing, and maintenance.

Product Performance

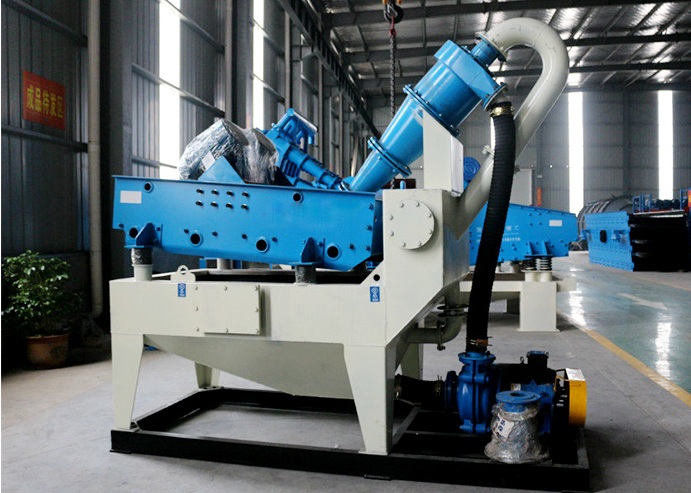

The modular crushing and screening station is a multi-integrated system solution composed of one or several crushing and screening unit modules according to the needs of the project. The structural design is compact, saving space and reducing the construction site area. The foundation is easy to handle and the equipment foundation is small, avoiding the difficulties of civil construction. All modules are pre-installed and assembled in the factory, shortening the on-site installation time. The equipment process is coordinated and smooth, the selection matching degree is high, and the operation efficiency is high. The equipment installation and maintenance are convenient, fast, safe and efficient. The modular station is easy to dismantle and reinstall, ensuring that the project can be quickly relocated and reassembled according to construction needs. All standard modules can be shipped by sea in standard containers.Working Principle

The working principle of the jaw crusher is to imitate the upper and lower jaw movements of animals to achieve material crushing. The equipment is mainly composed of two jaw plates, the movable jaw and the static jaw. The movable jaw is connected to the drive device through an eccentric shaft to achieve up and down movement. When the movable jaw moves downward, the material is placed in the crushing chamber and is squeezed between the movable jaw and the static jaw, and is gradually crushed into smaller particles.Technical Parameters

|

Specifications |

MJ-150 |

MJ-250 |

MJ300 |

MJ-450 |

MJ-650 |

MJ-850 |

|

|

Feed size(mm) |

530 |

720 |

800 |

800 |

910 |

1020 |

|

|

生产能力(t/h) |

120-150 |

150-250 |

250-300 |

300-450 |

450-650 |

650-850 |

|

|

单元总功率(kw) |

11+90 |

18.5+110 |

30+132 |

37+160 |

37+200 |

45+250 |

|

|

Main equipment configuration |

Feeder |

ZSW380*95 |

ZSW490*110 |

ZSW600*130 |

ZSW600*150 |

ZSW600*180 |

ZSW600*180 |

|

Jaw |

JC90 Or |

JC110 Or |

C1210 |

JC125 OR |

JC140 OR |

JC160 OR |

|

|

Main belt conveyor |

B800 |

B1000 |

B1000 |

B1200 |

B1200 |

B1400 |

|

|

Trash removal belt |

B500 |

B500 |

B500 |

B650 |

B650 |

B650 |

|

|

Main module structure |

Feed bin, equipment support, maintenance platform, ladder railing, inlet and outlet trough。 |

||||||