Popular searched products:

Product Description

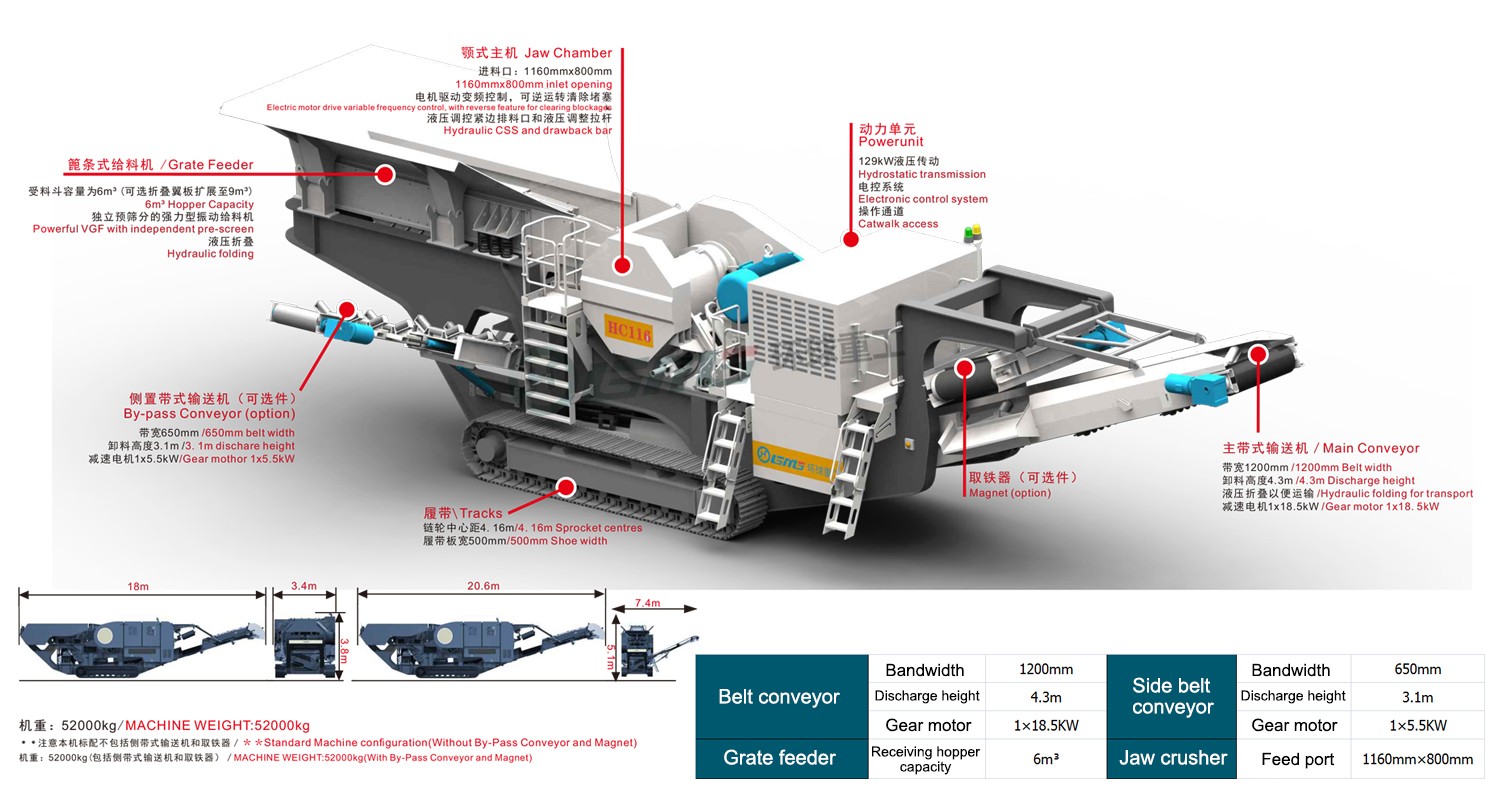

Jaw portable crusher is a new machine with large capacity, high cost performance,energy conservation and environmental protection. Continue incorporating HJ106 jaw crusher and aheavy duty vibrating grizzly feeder. Diesel engine is for tracking & folding. Plant need to be connectedto power supply to crushing and other operation. Incomparable advantages on efficiency, stabilityand cost-saving in versatility.

Product Performance

Electrical supply that can provide for all the operating, hydraulic needs of the plant, movement and folding for conveyor.

Compared with equipment driven by diesel on tracking and operation, the equipment provides a largepower cost reduction for customers.

Maintain tracked equipment's ease of transportation and superiority of starting production quickly in sites.

Supply external power in operation while turning engine off. Save maintenance costs greatly throughreduce running time of engine and hydraulic system.

Electricity drive in operation makes keeping high crushing efficiency available in high-altitude areas.

Working Principle

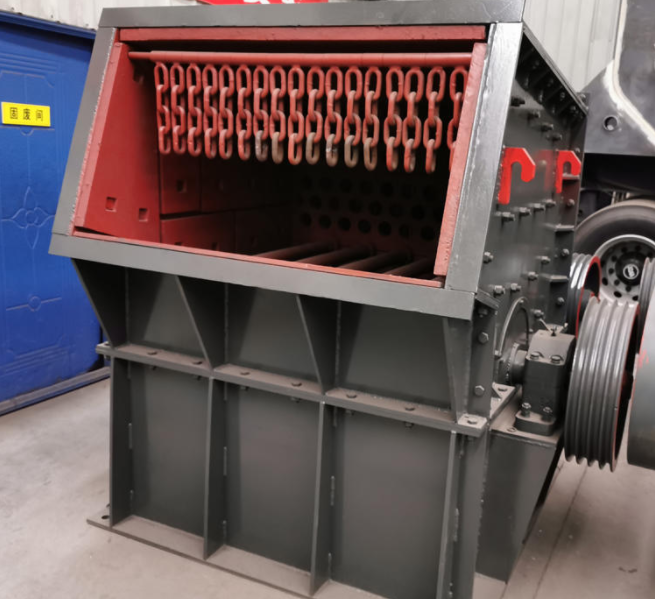

The material is uniformly transported to the crusher by the feeder. After the jaw crusher is preliminarily broken, the closed circuit system is formed by the circular vibrating screen to realize the circulating crushing of the material. The finished material is output by the conveyor for continuous crushing operation. The Jaw portable crusher can remove the circular vibrating screen according to the actual production needs, and realize the preliminary crushing of the material directly. It is convenient and flexible to use with other crushing equipment.

Technical Parameters

| HJ116 | HJ106 |

| Motice Power | |

| Crawler travel and equipment stretch folding | Crawler travel and equipment stretch folding |

| Crusher and belt conveyor:electrical supply | Crusher and belt conveyor:electrical supply |

| Total motor Power | |

| 188kW | 131kW |

| Crusher motor power 160kW | Crusher motor power 132kW |

| Variable frequency starting | Variable frequency starting |

| Jaw Chamber | |

| 1160x800mm single toggle jaw crusher | 1060x700mm single toggle jaw crusher |

| Hydraulically discharge opening adjustment by press button | Hydraulically discharge opening adjustment by press button |

| CCS range-100-225mm | CCS range-70-200mm |

| S-tooth liners standard,18%manganese | S-tooth liners standard,18%manganese |

| Feeder Hopper | |

| Hopper 6 m³ (9 m³ optional) | Hopper 6 m³ (9 m³ optional) |

| Hydraulically folding sides | Hydraulically folding sides |

| Pan feeder:length 4200mm,width 1100mm | Pan feeder:length 4200mm,width 1100mm |

| Grizzly feeder with integral pre-screen standard 40-70mm spacing | Grizzly feeder with integral pre-screen standard 40-70mm spacing |

| Selectable discharge to by-pass conveyor or main conveyor | Selectable discharge to by-pass conveyor or main conveyor |

| Mesh aperture on grizzly feeder 38mm | Mesh aperture on grizzly feeder 38mm |

| Main Conveyor | |

| 1200mm wide main belt fitted with impact bars at feed point | 1200mm wide main belt fitted with impact bars at feed point |

| High spec scraper at head drum | High spec scraper at head drum |

| Piped for dust supression complete with spraybars | Piped for dust supression complete with spraybars |

| General | |

| Separate operators panel | Separate operators panel |

| Provide hanging iron picker bracket and spare interface | Provide hanging iron picker bracket and spare interface |

| Galvanised catwalk c/w handrail,kick board and access ladders | Galvanised catwalk c/w handrail,kick board and access ladders |

| Meets safety standards for quarrying | |

| Heavy duty undercarriage unit with 500mm wide pads | Heavy duty undercarriage unit with 500mm wide pads |

| Control operation of tracks via hand held set with 5m connection lead | Control operation of tracks via hand held set with 5m connection lead |

| The on board electrical panel has manually switchable single phase and 3 phase power outlets | The on board electrical panel has manually switchable single phase and 3 phase power outlets |

| Emergency stops(6nr) | Emergency stops(6nr) |