Popular searched products:

Product Description

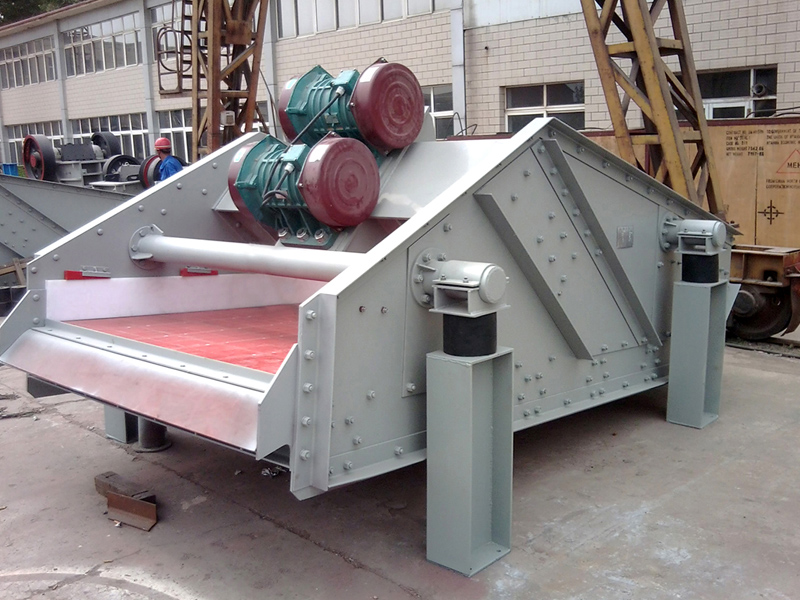

The high-frequency screen is composed of a vibrator, a slurry distributor, a screen frame, a frame, a suspension spring and a screen.

High frequency screen has high efficiency, small amplitude and high screening frequency. Different from the principle of ordinary screening equipment, because the high frequency screen uses high frequency, on the one hand, it destroys the tension on the surface of the slurry and the high-speed oscillation of fine-grained materials on the screen surface, accelerating the separation and separation of large-density (specific gravity) useful minerals. The effect increases the probability that materials smaller than the separation particle size come into contact with the sieve holes. This creates better separation conditions, allowing materials smaller than the separation particle size, especially particles with heavy specific gravity, to pass through the sieve holes together with the slurry to become products under the sieve.

Product Performance

- 1New structural design

Adopting new principle design, it is a new structure screen vibrating screening machine, generally using nylon or stainless steel screen plates.

- 2High vibration intensity

The vibration frequency of the screen surface is 50Hz, the amplitude is 0~2 mm, and the vibration intensity is 8~10 times the acceleration of gravity. It is a general mechanical The vibration intensity of the vibrating screen is 2~3 times.

- 3High screening efficiency, not easy to block holes

The screen surface is not easy to block holes, high screening efficiency, large processing capacity, especially suitable for fine powder Screening of bulk materials, classification particle size 0.074~1mm.

- 4Easy installation, adjustable angle

The whole machine is supported by vibration damping, so that the ground basically does not bear dynamic loads, and there is no need to make a foundation, and it can be installed directly It can work normally on a solid and flat ground or an ordinary steel structure platform. The installation angle of the screen machine is convenient and adjustable, and the screen surface inclination angle can be adjusted according to the required mineral particle size.

Working Principle

First, the high-frequency screen generates high-frequency vibration force through a vibration motor, causing the screen surface to vibrate weakly. This weak vibration can quickly separate fine particles of material on the screen surface, thereby achieving the purpose of screening.

Secondly, the high-frequency screen adopts a special screen surface structure. The screen surface is covered with a layer of tiny holes, the size of which can be adjusted as needed. As the material passes through the screen surface, smaller particles are able to pass through the holes, while larger particles are blocked on the screen surface. This screening action can classify materials according to particle size and improve production efficiency.

Finally, the high-frequency screen is also equipped with a specialized vibration system and screening system. The vibration system can generate stable high-frequency vibration force to ensure the stability and accuracy of the screening process. The screening system can adjust screening parameters as needed to meet the screening requirements of different materials.

Technical Parameters

| Model | Output (t/h) | Power (kw) |

| GPS-4 | 15-25 | 0.72 |

| GPS-5 | 20-30 | 1.1 |

| GPS-6 | 24-36 | 1.5 |

| GPS-8 | 32-48 | 2.2 |