Popular searched products:

Product Description

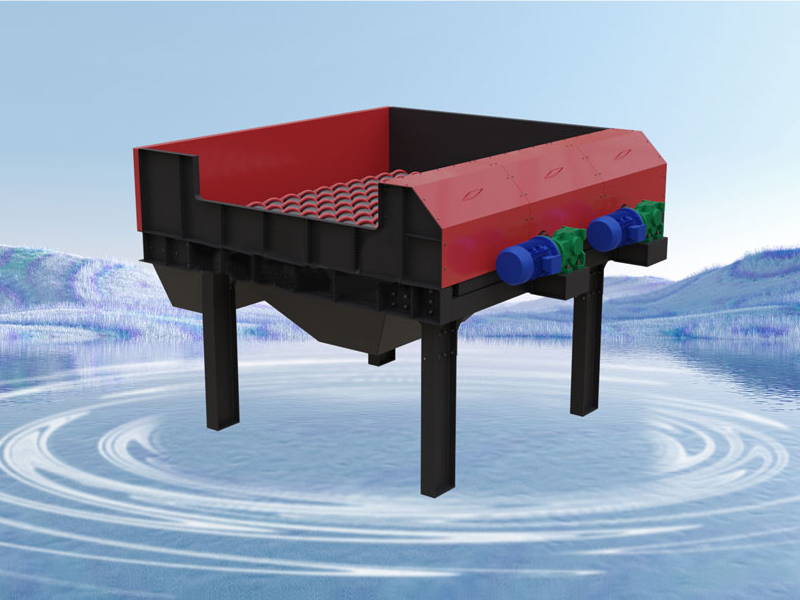

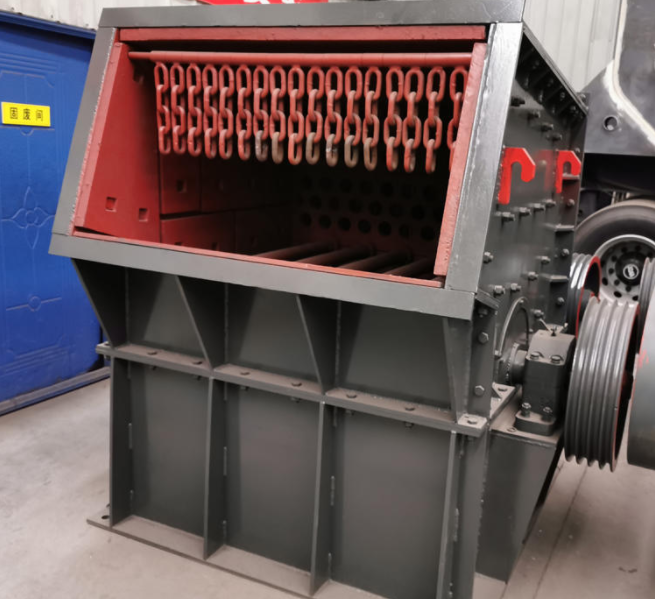

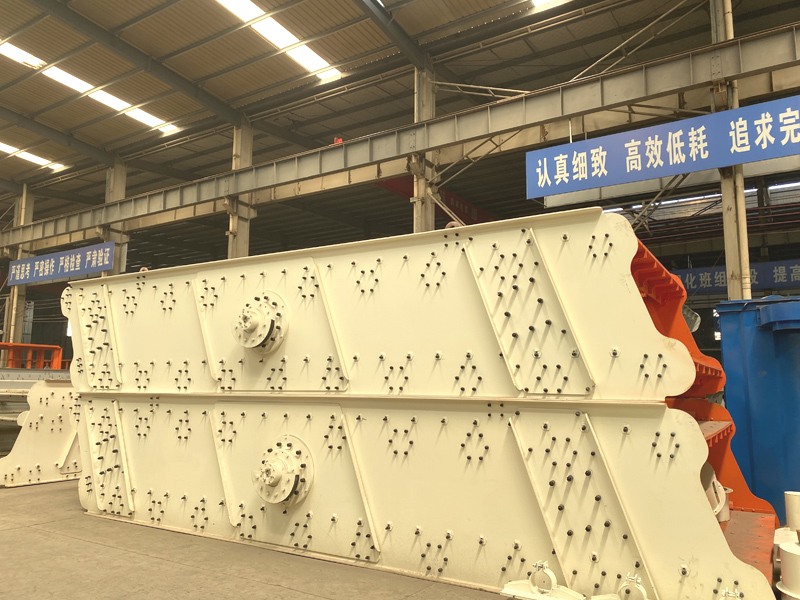

The power center of the spiral screen is composed of a spiral shaft, and there are several spiral blades on the spiral shaft according to different configurations. The compact design of the spiral shaft makes it ideal for the separation of viscous and wet materials. The spiral blade has almost no winding point, which can be sorted according to different specific gravity, hardness, size and shape, long hard materials (such as wood rods, iron pipes, etc.) and small pieces of material are separated separately, thereby reducing the load of subsequent sorting equipment. The pitch and diameter determine the size of the screening size, the material particle size range is 10-300mm, and can automatically adjust the running speed of each spiral shaft according to the material composition, humidity and so on.

Product Performance

- 1Advanced technology, energy saving

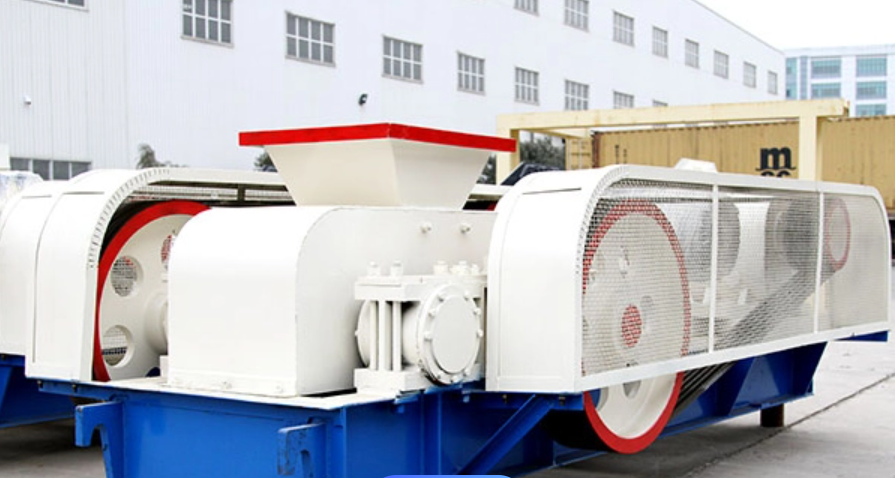

The equipment adopts frequency conversion control, high degree of automation, simple and convenient operation; In the closed grinding circuit, it can be connected with the mill flow, and the power consumption is lower than that of the hydrocyclone.

- 2Wide application range

It is widely used for classifying ore and fine mud in gravity concentrator, classifying pulp particle size in metal beneficiation process, desliming and dewatering in ore washing operation.

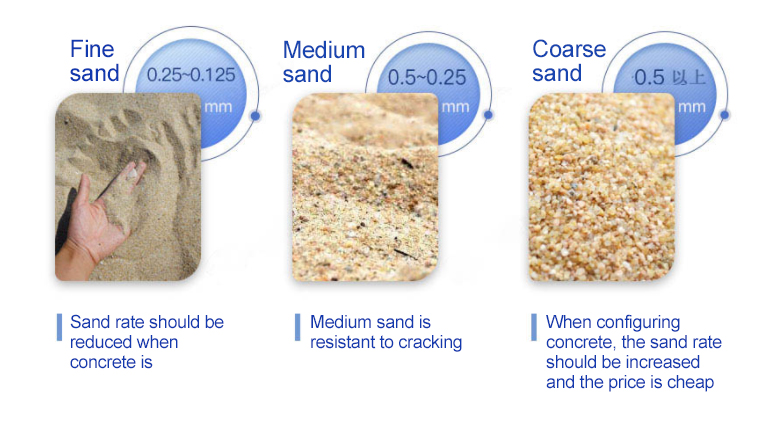

- 3High classification fineness, convenient adjustment, flexible

The classifier has a high fineness to eliminate large particles and screen residues in the product; The quality of stone powder is easy to control, and the fineness adjustment is convenient and flexible.

- 4The parts are wear-resistant and easy to maintain

The lower support of the machine adopts the structure of movable shaft sleeve and nylon bearing bush, which is convenient for maintenance and replacement; The base is made of channel steel, and the body is welded with steel plate. The inlet head and shaft head of the spiral shaft are made of cast iron sleeves, which are wear-resistant and durable.

Working Principle

When the screw screening machine is started, the screw rotates, the material entering the screen surface is propelled by the thread bar on the screw, and through the screw bar or groove and the screw groove or bar on the adjacent screw, the design of the screen between the product under the screen, the large-particle material is discharged at the end of the screw surface, and the small-particle material is discharged at the lower part of the screw surface, so as to achieve the effect of sorting and separation.

Technical Parameters

| Model | Screening size(mm) | Power |

| LXS3022 | 12 spiral axes | 2x11 |

| LXS3522 | 14 spiral axes | 2x15 |