Popular searched products:

Product Description

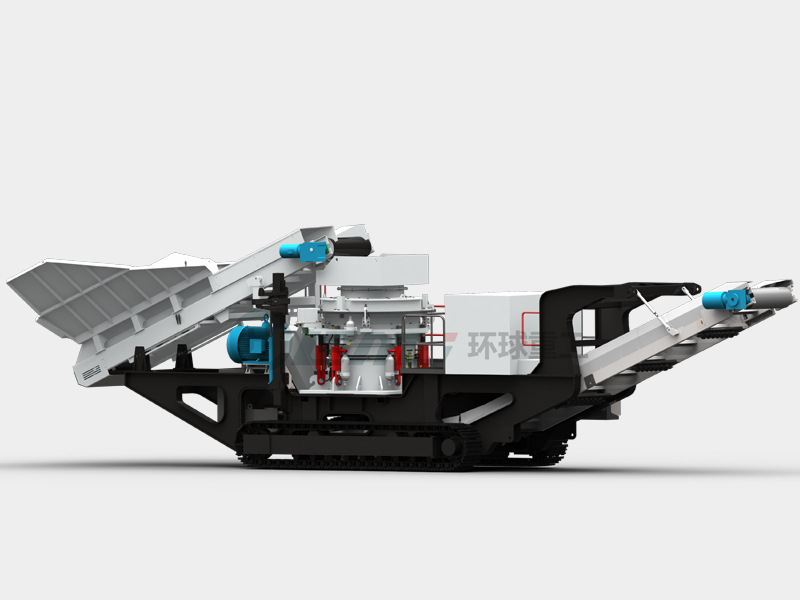

R series mobile crushing station can be divided into HI35R impact crushing station and Hj35r jaw crushing station, among which Hi35r is a mobile crushing station with good structural performance, the utility model has the advantages of compact structure, large crushing ratio, strong mobility, uniform discharging, simple operation, convenient transportation and convenient maintenance, etc. , the design of the rear screen system and the circulation conveyor allows the material to be graded and the oversized material to be sent back to the crusher for further crushing. Hj35r is a mobile crushing equipment which is composed of three systems: feeding, crushing and conveying. It adopts the integrated operation mode, the installation operation of complex site infrastructure and auxiliary facilities is eliminated, and the traditional fixed coarse crushing production line can be replaced in more application fields. In the application of various working conditions, its production efficiency, stability and power cost saving for users have incomparable advantages.

Product Performance

- 1Strong production capacity

A mature impact mobile crushing station with hydraulic overload protection function

Completely seal the hopper to avoid overflow

HPTO clutch and high efficiency fuel direct drive system

Powerscreen Pulse intelligent monitoring is standard . - 2Versatility

Area suitable for weight restriction;

The recirculation conveyor is hydraulically switched from recirculation to storage mode - 3Applicability

Excellent, unrestricted access to all key maintenance points

Product conveyor can be lowered during operation to avoid blockages and can be removed when servicing

Working Principle

Its working principle mainly includes the following steps:

1.Feed:The raw material is fed into the feed port of the mobile crusher by loading equipment such as loaders or excavators. The feed system usually includes a vibrating feeder, which is able to evenly feed the material into the crushing chamber.

2.Crush:After the raw material enters the crushing chamber, the crushing system begins to work. Crushing system is usually composed of crushing chamber, crushing hammer and crushing plate. The crushing hammer shocks, impinges and breaks the raw materials in a way of high-speed rotation. The crushing plate plays the role of guiding and controlling the particle size of the material. The broken material is discharged through the discharge port.

3.Sieving:The crushed material is further screened by conveyor belts or vibrating screen machines. Screening can be divided into different particle sizes according to needs to meet different application requirements.

4.Transport:The screened material is transported to the next process or storage area by conveyor belt or stacker equipment. The conveying system can realize the continuous conveying and stacking of materials.

5.Controls:The mobile crusher is usually equipped with a control system for monitoring and controlling the operating status and working parameters of the equipment. The operator can start and stop, adjust and troubleshoot the crusher through the control system.

Technical Parameters

| Conveyor | |

|---|---|

| Bandwidth | 900mm |

| DISCHARGE HEIGHT | 3m |

| Circulation conveyor | Width: 500MM |

| Discharge Height: 3.1 M | |

| Fine Conveyor | Width: 1000 mm |

| Discharge Height: 2.5 M | |

| By-pass conveyor (optional) | Width: 500MM |

| Discharge Height | 2.4 M (7' 10'') hydraulic folding transport |

| General | |

| R series Hubei crusher inlet | 930mm x 580mm |

| R series impact crusher inlet | 1100mm x 1100mm |

| Hopper | 3.6m Long (11'10'') , 2m wide (6'7'') , capacity up to 2.6m |

| Single deck screen box, top deck | 2.44m X 1.2m |

| DRIVE | Hydraulic Motor |

| Track width | 400 MM |

| Length of feeder | 3.6m |

| Vibrating screen feeder screening area | 3000m×1000mm |