Popular searched products:

Product Description

The crawler impact station is a mobile crushing equipment with an impact crusher as the host machine. It is generally used for secondary crushing equipment in the entire crushing process. The impact crusher plays a very high role in demolishing old buildings. It can crush and screen construction waste into several recycled aggregates of different sizes and rules. It is the basis for the project to realize the resource reuse of construction waste in my country.

Product Performance

- 1Wireless remote control

Through wireless remote control, it is very easy to drive the equipment onto the trailer and transport it to the work site, intelligently More convenient to operate.

- 2High operating efficiency

Adopting an integrated combined operation method, no assembly time is required, and you can start work immediately upon arrival at the work site.

- 3Supports mixed use of oil and electricity

The equipment can be equipped with a generator set to meet the normal operation requirements in complex situations such as no power or power outage and ensure continuous operation , reduce losses.

- 4Environmental protection standards

The use of crawler mobile crushing stations is fully environmentally friendly and energy-saving. Many pollution factors such as loud noise and dust diffusion during the production process are eliminated. was reasonably resolved.

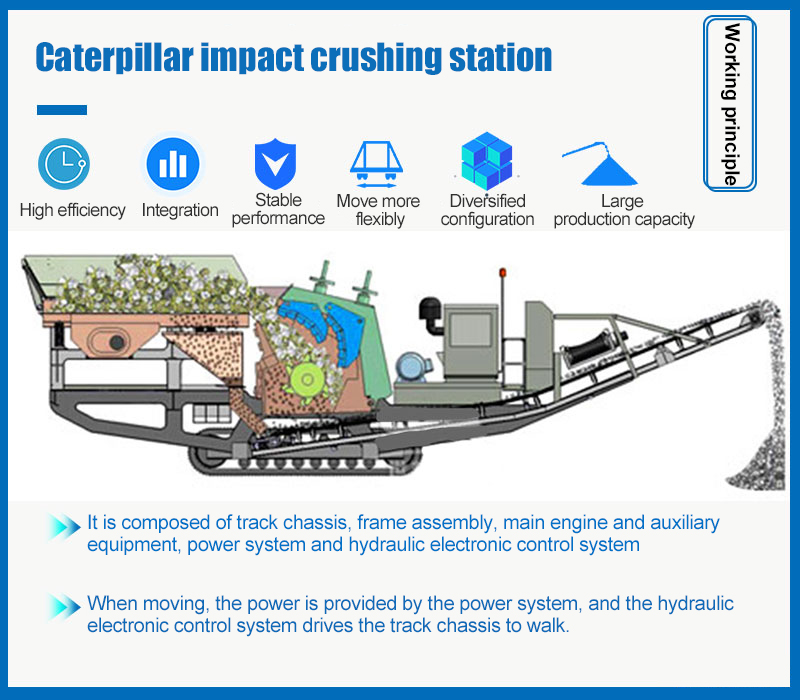

Working Principle

The raw materials are sent into the silo through forklifts, excavators and other equipment. The materials in the silo enter the screening feeder. The part of the raw materials with the required particle size leaks from the sieve holes and is directly passed through the unearthed belt conveyor. Mounds are formed; larger materials enter the AF impact crusher through the screening feeder for crushing, and then when the particle size reaches the standard, they are discharged from the discharge port into the vibrating unloader; the unloader sends the materials evenly It enters the main discharge belt conveyor, and the belt conveyor transports the materials out to form a material pile; at the same time, an iron remover is installed above the main discharge belt, and the iron in the materials is separated after being attracted by the iron remover.

Technical Parameters

| Project | Unit | TAF270 | TAF340 | TAF380 | TAF430 |

| Economic Feed | mm | ≤400 | ≤500 | ≤600 | ≤600 |

| Processing volume | t/h | 100-200 | 150-250 | 200-300 | 300-400 |

| Installed power | KW | 237.4 | 287.4 | 330.9 | 365.1 |

| Traveling engine power | KW | 75 | 75 | 90 | 110 |

| Working dimensions (length x width x height) |

mm | 14550 x 5950 x 4550 | |||

| Transportation dimensions (length x width x height) |

mm | 12600 x 3300 x 3100 | 14550 x 3300 x 3200 | ||