Popular searched products:

Product Description

The mobile crushing station is a piece of equipment that is widely welcomed by sand and gravel plants. It is highly mobile and easy to move between sites. It eliminates the complicated installation process during the crushing process, saving money and time.

The mobile crushing station can be directly driven to the stone quarry for operation, reducing material transportation costs, and the configured screening system can directly meet the customer's finished product particle size requirements. It is suitable for operations in areas with small crushing sites and narrow terrain, and is used in construction waste crushing and processing The field effect is significant. The mobile crushing station is reliable in operation, easy to operate and has many energy-saving advantages.

Installation site of crawler cone crushing station

Construction site of crawler cone crushing station

Product Performance

- 1Highly independent and complete set

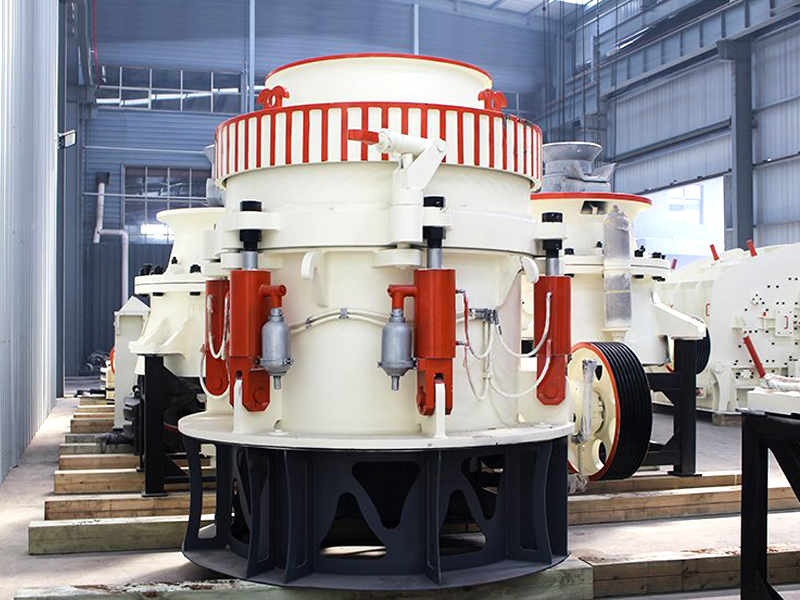

Equipped with a cone crusher suitable for medium and fine crushing with excellent performance, special crushing wall and rolling mortar wall design, supplemented by The curved cavity type and hydraulic cavity cleaning system improve crushing efficiency and effectively reduce easy operation losses.

- 2Highly mobile and easy to operate

Using a fully automatic crushing control system, quick response to overload (overload), automatic release reset protection, wireless remote control operation, It can reduce the number of equipment operators and ensure continuous, stable and efficient production.

- 3Strongly independent and complete set

Equipped with PLC control system to maintain a full cavity and continuous feeding, and the final product is in the form of high-quality cubes. The configuration is reasonable, the process is smooth, the production efficiency is high, the product has good grain shape, and the final product is in the form of high-quality cubes.

- 4Good production performance

Large eccentricity, high swing frequency and layer compression crushing make the equipment high output, large crushing ratio and good particle shape.

Working Principle

A. When moving, power is provided through the power system, and the hydraulic electronic control system controls and drives the crawler chassis to move;

B. During installation, the power system controls the driving of the hydraulic cylinder and other actions through the hydraulic electronic control system to automatically complete the equipment installation;

C. When working, the power system drives and controls the work of the host and auxiliary equipment through the hydraulic and electronic control system. After the materials enter the host machine mounted on the crawler chassis and frame from the silo for crushing or screening, they pass through the integrated belt machine discharge.

Technical Parameters

| Model | 160SC | 250SC | 300HPM | 400HPM | |

| Transportation dimensions | Length | 16800mm | 19000mm | 19000mm | 19500mm |

| Width | 3500mm | 3600mm | 3900mm | 3900mm | |

| Height | 3700mm | 3800mm | 3800mm | 3800mm | |

| Weight | 50t | 60t | 55t | 65t | |

| Loading conveyor | hopper volume | 3m³ | 3m³ | 3m³ | 3m³ |

| Loading height | 2600m | 2600m | 2600m | 2800m | |

| Loading width | 1900mm | 1900mm | 1900mm | 1900mm | |

| Dimensions (width×length) | 1000×6300mm | 1000×6300mm | 1000×6300mm | 1200×6500mm | |

| Crusher | Model | SC160 | SC250 | HP300 | HP400 |

| Feeding port | 75-360mm | 75-450mm | 60-200mm | 68-280mm | |

| Maximum feed port size | 360mm | 450mm | 200mm | 280mm | |

| Minimum discharge port | 8-25mm | 8-35mm | 8-45mm | 8-51mm | |

| Main belt conveyor | Dimensions (width×length) | 1000×9000mm | 1000×10000mm | 1000×10000mm | 1000×11000mm |

| Discharge height | 3100mm | 3490mm | 3490mm | 3690mm | |

| Return screen | Discharge height | 4200mm | 4200mm | 4400mm | 4400mm |

| Model | HX1536 | HX1536 | HX1536 | HX1536 | |

| Screen mesh specifications | 1500×3600mm | 1500×3600mm | 1500×3600mm | 1500×3600mm | |

| Screen bottom belt conveyor | Dimensions (width×length) | 1000×5600mm | 1000×5600mm | 1000×5600mm | 1000×6500mm |

| Discharge height | 3020mm | 3020mm | 3020mm | 3300mm | |

| Screen head belt conveyor | Dimensions (width×length) | 650×2100mm | 650×2100mm | 650×2100mm | 650×2100mm |

| Discharging height | 1370mm | 1370mm | 1370mm | 1370mm | |

| Return belt conveyor | Dimensions (width×length) | 650×10000mm | 650×10000mm | 650×11000mm | 650×11000mm |

| Discharge height | 4200mm | 4200mm | 4400mm | 4400mm | |

| Diesel engine | Power | 96kw | 132kw | 106kw | 132kw |

| Manufacturer | Carter Perkins | Carter Perkins | Carter Perkins | Carter Perkins | |

| Complete machine | Power | 207.12kw | 297.12kw | 267.12kw | 362.12kw |

| 控制方式 | Wired/wireless (optional) | Wired/wireless (optional) | Wired/wireless (optional) | Wired/wireless (optional) | |