Popular searched products:

Product Description

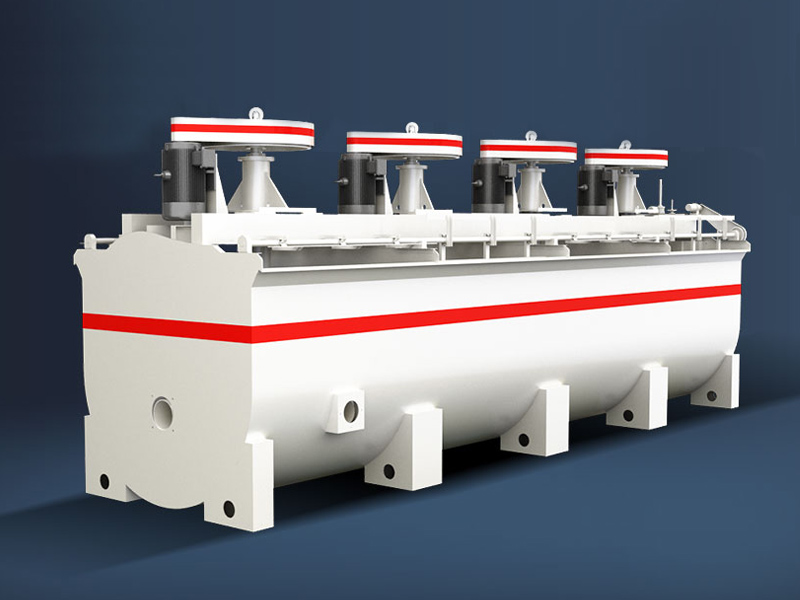

The BF flotation machine is a new type of flotation equipment that has the dual functions of slurry suction and flotation. The machine has a novel structure and superior performance. It is an improved product based on the original SF flotation machine through optimized design. The working room can be horizontal. Configuration, the medium ore foam can self-return, self-absorb slurry, and self-aspirate air. It consumes less power than the A-type flotation machine, has a large air suction volume, and has a low impeller peripheral speed. The slurry in the tank is circulated in a fixed flow pattern, with Conducive to the suspension of coarse minerals.

Product Performance

- 1It costs less to operate

Compared with conventional mechanical agitation flotation machines, it can save 1/3~1/2 of electricity.

- 2High sorting accuracy and low ash content of clean coal

The ash content of clean coal can be reduced by 1~2% compared with conventional mechanical stirring flotation machines.

- 3Good flotation effect

It is equipped with automatic liquid level control and electronic control device, and the foam is highly refined, thus improving the flotation effect.

- 4The wearing parts are highly durable

The impeller is always active in the machine, which plays a role in removing accumulated materials and debris, reducing Damage to components due to debris; and the impeller of the mixing device is made of ground rubber, which enhances wear resistance.

Working Principle

Add water and necessary chemicals to the ground ore during or after grinding to form a slurry in a mixing tank, then pour it into the slurry tank where the stirring begins, and introduce air into the slurry to form a large number of bubbles. Mineral particles that are not easily wetted by water, generally called hydrophobic, adhere to the bubbles and float to the surface of the slurry together with the bubbles to form a mineralized bubble layer. Others that are easily wetted by water are generally called hydrophilic. The mineral particles do not attach to the bubbles, but remain in the slurry, and the mineralized bubbles containing specific minerals are discharged, thereby achieving the purpose of mineral processing.

Technical Parameters

| Model | Trough volume | Internal dimensions (L×W×H) (m) | Air suction volume (m³/min) | Installed power (kw) | Motor model | Processing capacity (t/h) | Single tank weight (t) |

| BF-0.37 | 0.37 | 0.74×0.74×0.75 | 0.9~1.05 | 1.5 | Y90L-4 | 0.2~0.4 | 0.5 |

| BF-0.65 | 0.65 | 0.85×0.95×0.9 | 0.9~1.10 | 3 | Y132S-6 | 0.3~0.7 | 1 |

| BF-1.2 | 1.2 | 1.05×1.15×1.10 | 1.0~1.10 | 5.5 4.0 | Y132M2-6 Y132M1-6 | 0.6~1.2 | 1.4 |

| BF-2.0 | 2 | 1.40×1.45×1.12 | 1.0~1.10 | 7.5 | Y160M-6 | 1.0~2.0 | 1.8 |

| BF-2.8 | 2.8 | 1.65×1.65×1.15 | 0.9~1.10 | 11 | Y180L-8 | 1.4~3.0 | 2.2 |

| BF-4.0 | 4 | 1.9×2.0×1.2 | 0.9~1.10 | 15 | Y200L-8 | 2~4 | 2.6 |

| BF-6.0 | 6 | 2.2×2.35×1.3 | 0.9~1.10 | 18.5 | Y225S-8 | 3~6 | 3.3 |

| BF-8.0 | 8 | 2.25×2.85×1.4 | 0.9~1.10 | 22 30 | Y225M-8 Y250M-8 | 4~8 | 4.2 |

| BF-10 | 10 | 2.25×2.85×1.7 | 0.9~1.10 | 22 30 | Y225M-8 Y250M-8 | 5~10 | 4.7 |

| BF-16 | 16 | 2.85×3.8×1.7 | 0.9~1.10 | 37 45 | Y280S-8 Y280M-8 | 8~16 | 8.4 |

| BF-20 | 20 | 2.85×3.8×2.0 | 0.9~1.10 | 37 45 | Y280S-8 Y280M-8 | 10~20 | 8.7 |

| BF-24 | 24 | 3.15×4.15×2.0 | 0.9~1.10 | 45 | Y280M-8 | 12~24 | 9.2 |