Popular searched products:

Principle, Structure, and Inspection Points of Osepa Powder Selection Machine

The OSEPA powder selector was developed by Onoda Corporation in Japan in 1979, also known as the "third-generation high-efficiency powder selector", and has been widely used in the grinding system of cement enterprises. As an efficient powder sorting equipment, the Osepa powder separator is widely used in grinding systems in industries such as cement, mining, and metallurgy. Its working principle and structural characteristics determine its superior performance in the field of powder sorting, and correct inspection operations are the key to ensuring its stable operation. This article will provide a detailed introduction to the principle, structure, and inspection points of the Osepa powder selector.

1. Working principle of Osepa powder selection machine

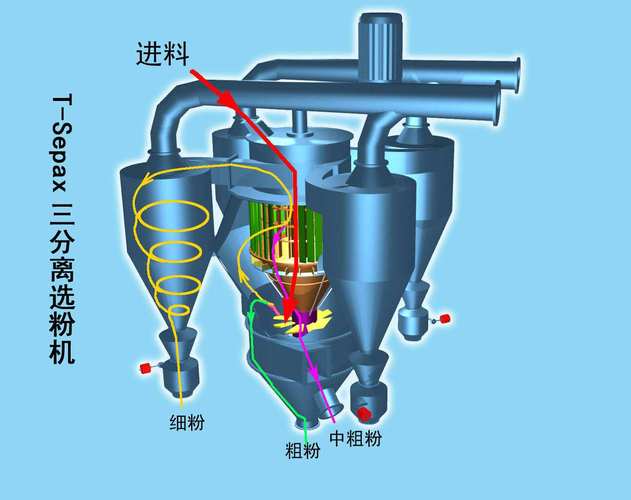

The working principle of Osepa powder selection machine is based on the grading effect of materials in the airflow. After the material enters the powder selection machine through the feeding pipe, it first passes through the dispersing plate and is scattered into the rising airflow. The grinding medium fragments in the material overcome the resistance of the rising airflow and fall under the action of gravity, and are discharged through the slag discharge outlet. The airflow carrying the powder rises to the grading section and enters the rotor for grading through guide vanes.

Under the action of the rotor, the airflow and powder particles undergo rotational motion for pre classification. The guide vanes not only evenly distribute the airflow velocity throughout the height of the rotor, but also capture the coarse particles thrown out by the rotor. The captured coarse particles fall onto the coarse powder cone and are discharged through the coarse powder outlet. And fine particles and airflow enter the middle of the rotor through the rotor blades, and are sent to the collection device through the fine powder outlet.

2. Working principle of Osepa powder selection machine

The working principle of Osepa powder selection machine is based on the grading effect of materials in the airflow. After the material enters the powder selection machine through the feeding pipe, it first passes through the dispersing plate and is scattered into the rising airflow. The grinding medium fragments in the material overcome the resistance of the rising airflow and fall under the action of gravity, and are discharged through the slag discharge outlet. The airflow carrying the powder rises to the grading section and enters the rotor for grading through guide vanes.

Under the action of the rotor, the airflow and powder particles undergo rotational motion for pre classification. The guide vanes not only evenly distribute the airflow velocity throughout the height of the rotor, but also capture the coarse particles thrown out by the rotor. The captured coarse particles fall onto the coarse powder cone and are discharged through the coarse powder outlet. And fine particles and airflow enter the middle of the rotor through the rotor blades, and are sent to the collection device through the fine powder outlet.

3. Key points of inspection

Preparation before inspection: Inspection personnel should be familiar with the structure and working principle of the Osepa powder selector, and understand the purpose and requirements of the inspection. Before inspection, necessary tools and safety protective equipment should be prepared to ensure safety during the inspection process.

Equipment appearance inspection: Observe whether the appearance of the powder selection machine is clean, whether the connections of each component are tight, and whether there are any looseness, breakage, or other phenomena. Check whether each inspection door is tightly closed and whether each airflow regulating valve is in the normal position.

Transmission device inspection: Check the operation of transmission components such as motors, reducers, and couplings, and observe whether there are any abnormal sounds, vibrations, or heating phenomena. Check the lubrication condition of the transmission components to ensure that the lubricating oil level is normal and the oil quality is clean.

Rotary inspection: Observe whether the rotor runs smoothly, whether the feeding tray is intact, and whether the feeding is uniform. Check if the gap between the rotor and the housing is normal and if there are any foreign objects stuck in.

Shell and pipeline inspection: Check the shell for defects such as wear, deformation, or cracks. Check whether the feeding hole, observation hole, manhole, and maintenance door are well sealed and free of air leakage. Check if the connections of each pipeline are secure and if there are any leaks.

Lubrication system inspection: Check whether the oil pump, oil tank, oil pipe and other components of the lubrication system are intact, whether the lubricating oil is sufficient and clean. Observe the lubrication condition of the lubrication points to ensure good lubrication and no leakage.

Operating parameter check: Check whether the operating parameters such as current, voltage, and speed of the powder selector are normal. Observe the powder selection effect to ensure that the product quality meets the requirements.

By regularly inspecting the Osepa powder selection machine, potential safety hazards and malfunctions can be identified and addressed in a timely manner, ensuring the stable operation of the equipment and improving production efficiency. At the same time, during the inspection process, the operation of the equipment can also be recorded and analyzed, providing strong support for the maintenance and management of the equipment.

Related Reading

- What is machine-made sand? Why is machine-made sand so popular? What are the advantages of machine-made sand?

- Regarding the price of mobile sand making machines, manufacturer recommendations, and sand blasting effects, this article has everything you want to know!

- To improve the sand and gravel technology, save energy and increase efficiency, and improve the quality of sand production, you should read this article carefully!

- I heard that the profit of machine-made sand washing is good, how much is it? Which equipment is suitable for machine-made sand washing?

- If you want to choose a cost-effective truck-mounted mobile sand washing machine, Zhengzhou Global Heavy Industry is your first choice

- If you want to make sand washing production and processing more flexible, mobile sand washing station is your first choice!

Product show

Product

Source:

Source: Time:2024/08/22 16:29:47

Time:2024/08/22 16:29:47