Popular searched products:

Product Description

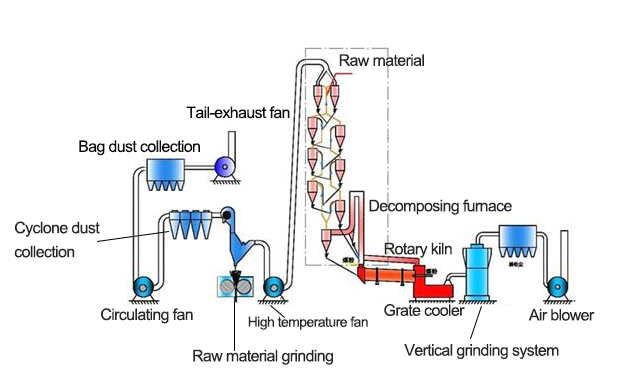

The cyclone preheater can utilize the high-temperature airflow accumulated and tumbling in the kiln, and adopt a multi-stage circulating suspension preheating method to fully exchange heat between the raw material powder and the hot airflow, complete suspension preheating and partial raw material decomposition, and prepare for the raw material to enter the kiln for calcination.

The cyclone preheater can make full use of the heat in the kiln, reduce the heat consumption of clinker burning, and reduce the floor space of the burning equipment. Our company conducts professional design for customers in different regions and production scales to achieve ideal use effects. At present, the five-stage cyclone preheater is the most widely used.

The vertical cyclone preheater system is mainly composed of six parts

1. Upper feeding system: mainly including the upper silo and the feeding pipe. The feeding method and structure can ensure safe and closed feeding into the preheater body, so that the cold air from the outside cannot enter the preheater, and the feeding can be realized continuously or intermittently with the help of the rod valve.

2. Preheater body: It is an important part to ensure that the material is preheated to about 900 degrees Celsius. It is composed of preheating chamber, suspension device and refractory brick lining (this item does not belong to the scope of equipment design and manufacturing). Most of the structure of this part is metal components, and some materials are selected from heat-resistant steel according to needs. Heat-resistant steel can work at high temperatures of 1000~1100 degrees Celsius. In addition, the refractory brick lining structure is novel in design and has good sealing, which can ensure that the material is evenly preheated in the preheater and reaches the preheating temperature.

3. Pushing device: mainly includes pusher head, frame and connecting rod. The pusher head is cast or welded with heat-resistant steel and can withstand high temperature. With the help of electronic control and hydraulic system, each hydraulic push rod can push materials in sequence according to the automatic control program.

4. Hydraulic system: mainly includes oil tank, oil pump, motor, solenoid valve, hydraulic oil pipe, etc. Its main function is to control the pushing device and complete the pushing action.

5. Lower feeding chamber: mainly includes chute, feeding chamber body, feeding chute, etc. Its main function is to introduce the preheated materials into the rotary kiln for calcination.

6. Frame: It mainly includes columns, ring beams, etc., and its main function is to bear the upper structure of the preheater.

Product Performance

- 1High production efficiency

Since the cyclone preheater adopts a multi-stage circulating suspension preheating method, the production efficiency is improved.

- 2Low production energy consumption

The equipment allows full utilization of the heat in the kiln, reduces the heat consumption of clinker burning, has very low energy consumption, and reduces the floor space occupied by the burning equipment.

- 3Long service life

The cyclone preheater has a reasonable structure, reduces equipment failures, is economical and durable, and can be said to have low investment and high profits.

- 4Good raw material adaptability

The cyclone preheater has good preheating effect, strong raw material adaptability, low system pressure loss, high kiln decomposition rate, anti-blocking, and good sealing.

Working Principle

It uses the high-temperature airflow accumulated and tumbling in the kiln, and adopts a multi-stage circulating suspension preheating method to make the raw material powder and the hot airflow fully exchange heat, complete the suspension preheating and partial raw material decomposition, and prepare for the raw material to enter the kiln for calcination.

The cyclone preheater system is mainly composed of six parts: the upper feeding system, the preheater body, the pusher, the hydraulic system, the lower feeding chamber, and the lower feeding chamber.

Technical Parameters

| Product name | Model specifications | Product name | Model specifications |

| Cyclone heater with decomposition furnace | RF5/500 (KSV-5) level | 600t/d five-stage cyclone preheater | RX5/600 |

| RF5/800 (KSV-5) Level 5 | |||

| RF5/1000 (KSV-5) Level 5 | RX5/300 | ||

| RF5/2500 (KSV-5) Level 5 | |||

| RF5/1800 (RSP) Level 5 | |||

| RF5/1200 (DD furnace) Level 5 | |||

| RF5/2500 (DD furnace) Level 5 | |||

| RF5/1200(N-MFC) Level 5 | Lime preheater | k-k/600 | |

| 280t/d five-stage cyclone preheater | RX5/280 | 2000t/d kiln external decomposition system | RF5/2000 (KSV-5) level |