Popular searched products:

Product Description

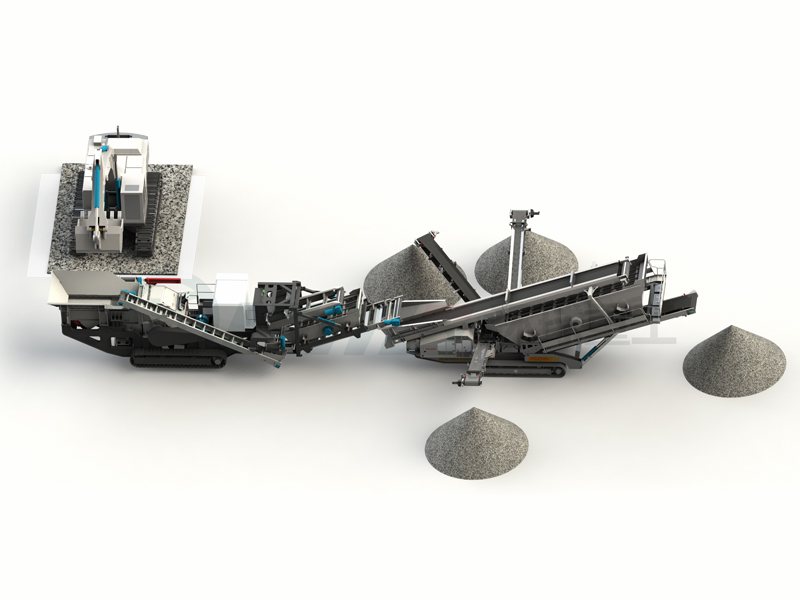

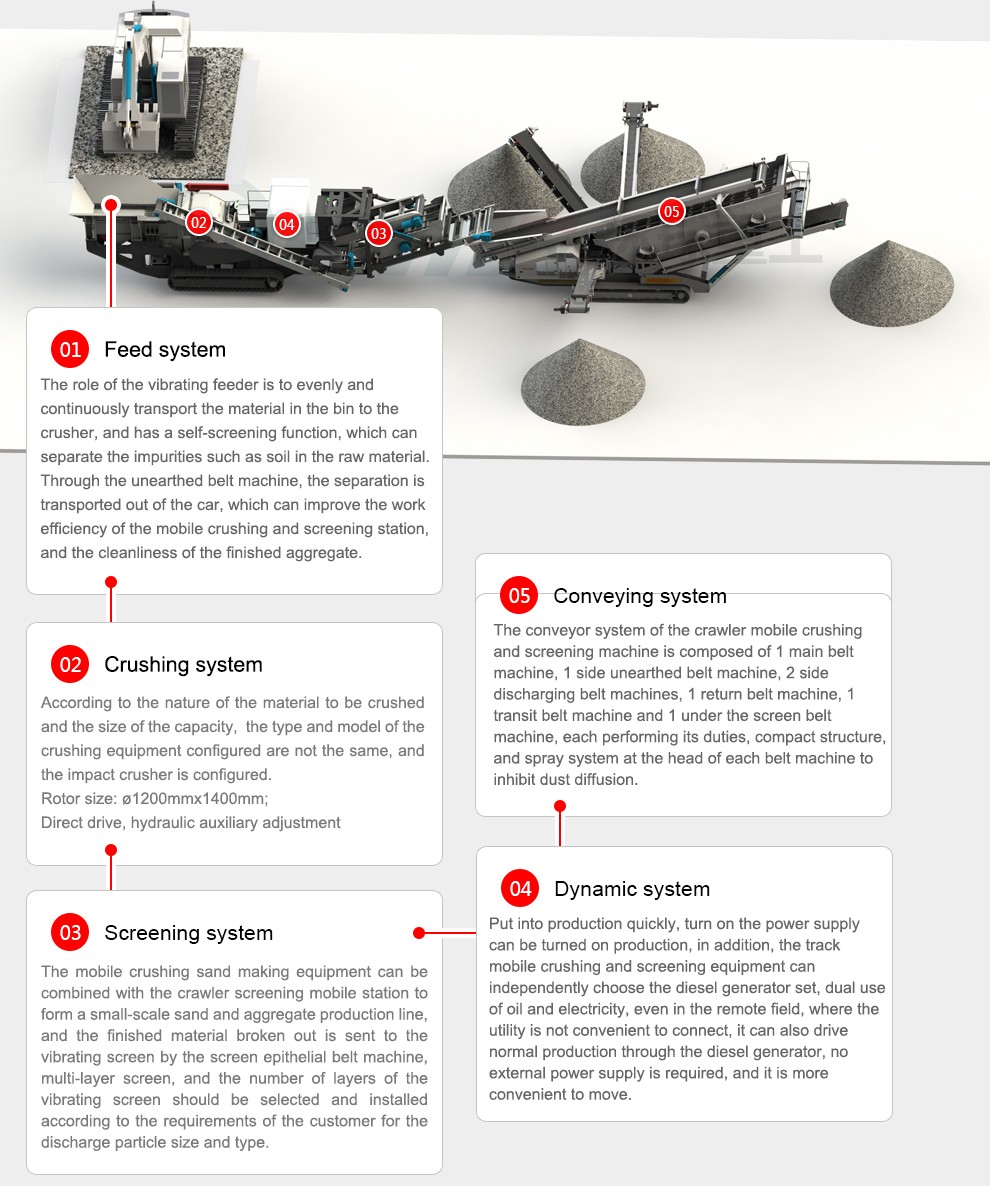

The crawler mobile crushing and screening machine group takes the impact crusher as the main machine, integrates the crushing and screening, has a compact structure, simplifies the crushing process, and is an excellent choice for the crushing of ore and construction waste, with advanced technology and complete functions.

The crawler mobile crushing and screening machine group adopts the crawler chassis, which can be supplied with its own generator set (optional) or external power supply in two ways, which is convenient for transfer and can be applied to a variety of harsh environments.

Product Performance

1, crawler crushing and screening machine configuration is flexible, diverse functions

2, oil and electricity dual use, ensure production, reduce losses

3, moving gravel, saving time and effort

4, EIA standards, let you worry about gravel

5, price scientific pricing, economic

Working Principle

Raw materials are fed into the silo by forklifts, excavators and other equipment, and the material in the silo enters the screening feeder, where the part of the raw materials with the required particle size leaks down from the screen hole and directly forms the mound through the unearthed belt conveyor; The larger material is broken through the screen feeder into the impact crusher, and then when the particle size reaches the standard, it is discharged from the discharge port into the vibration discharge machine; The discharging machine evenly sends the material to the main discharging belt machine, and the belt machine transports the material out to form a material pile; At the same time, an iron remover is installed above the main discharge belt, and the iron in the material is separated after being drawn by the iron remover.

The mixture (that is, the output of the crushing truck) enters the upper layer of the vibrating screen through the main feeding belt, forms different particle size aggregate levels after screening, and is transported to the material pile of different particle size through the finished belt to form the finished pile. The upper layer of the vibrating screen is the large particle size material that does not meet the requirements, and then returns to the crushing car for secondary crushing. If it is not used in conjunction with the crushing truck, it can be directly formed into a material pile.

Technical Parameters

| Feeding equipment | |

|---|---|

| Volume(m³) | 6 |

| Grate clearance(mm) | 50 |

| Feeder screen(mm) | 38 |

| Crusher | |

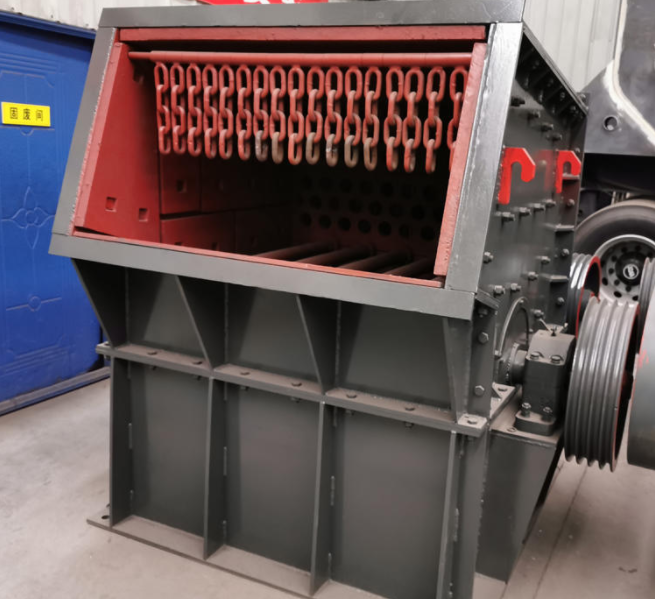

| Type of crushing engine | Impact crusher |

| Rotor(mm) | 1400×1200 |

| Number of screen layers | 3 |

| bandwidth(mm) | 650 |

| Belt conveyor | |

| Width of main belt conveyor(mm) | 1200 |

| Intermediate material belt conveyor unloading height(m) | 4.7 |

| Large material belt conveyor discharge height(m) | 4.4-5.3 |

| Whole machine | |

| Overall power(kw) | 226 |

| Capacity(t/h) | ≤425/tph |

| Machine weight(t) | 74 |

| Transport dimensions:length × width × height(m) | 14.7×2.95×3.8、19.3×3×3.5 |