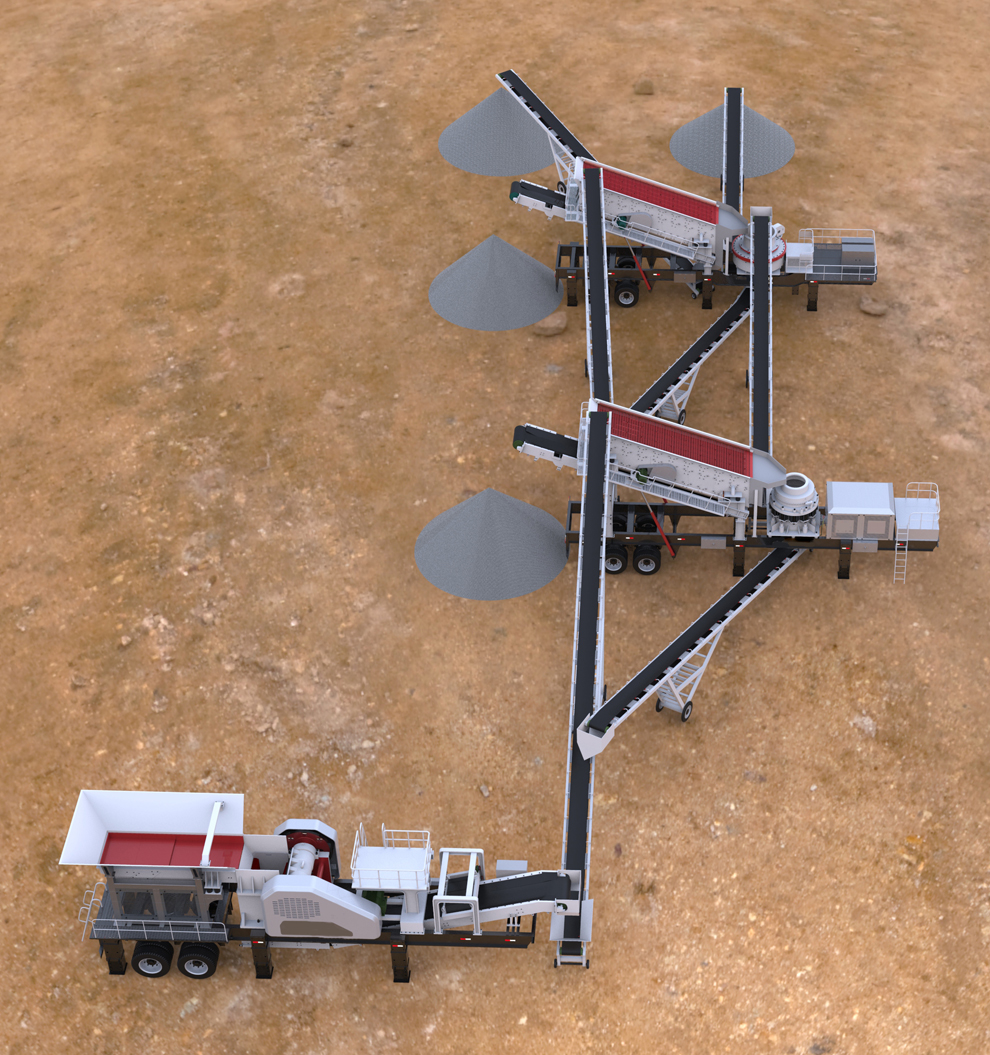

Mobile cone crushing station construction waste sand production line

Production Capacity:500t/h

Processing materials:Construction waste, waste concrete, rock, limestone, etc

Power Consumption:

Production Capacity:500t/h

Processing materials:Construction waste, waste concrete, rock, limestone, etc

Power Consumption:

Global Heavy industry quality is good

When designing this production line, the designers of Global Heavy Industries took into account the characteristics of construction waste materials, which can meet the particle size requirements of construction waste products; It can also meet the crushing effect of construction waste; To this end, Global Heavy Industry designed this cone mobile station construction waste crushing sand production line for customers.

Scheme design: 500t/h construction waste, daily work 8h, discharge size adjustable

Configuration details: Construction waste mobile crushing station (jaw broken + cone broken)

Advantages of the production line: can mechanize the selection of steel bars and wood bars in construction waste, and then evenly break the waste such as residual soil, crushed stone, waste mortar, brick and tile fragments, the quality of the finished products is excellent, and the dust removal protection system is also used, which has the advantages of less dust and low noise, and has been recognized by the upper and downstream users.

Construction waste mobile crushing station has the advantages of high intelligence, time and labor saving, high efficiency, good quality of gravel and so on. And its output of finished products can be used to produce recycled, concrete aggregate and so on.

以上翻译结果来自有道神经网络翻译(YNMT)· 通用场景

First of all: jaw crusher is a common machine for crushing construction waste; The equipment is used for rough, medium and fine crushing of ores and rocks with compressive strength of 147-245MPa; In view of this feature, Global Heavy Industry engineers choose this machine as the first process of construction waste crushing,

The device is equipped with a wedge outlet adjustment device, which is simpler than the old gasket adjustment, and can meet the sand and stone specifications of the discharge particle size less than 30mm; The elbow plate of the jaw crusher is equipped with overload protection device. When crushing high-hardness construction waste, if there is more than the crushing capacity of the material (iron), these materials will damage the equipment, at this time the elbow will be automatically broken, protect the main machine from damage, to achieve stable crushing production.

Second: cone crusher is very suitable for crushing high hardness of construction waste; In the design, the speed, stroke and crushing cavity are optimized, and the layered crushing along the crystal is realized. Can meet the specifications of construction waste crushed products below 30 mm; With multi-chamber crushing capacity, the hydraulic locking cylinder with overload protection device can automatically stop when encountering undestructible materials to achieve double protection. Therefore, this production line takes the wheeled cone mobile crushing station as the second crushing process.Cone crusher is divided into three kinds: coarse cone crusher, medium cone crusher and fine cone crusher. Standard type suitable for medium crushing, medium suitable for fine crushing, short head type suitable for fine crushing, to meet the different needs of users for construction waste crushing.

Then the material broken out by the cone does not meet the requirements of the finished material into the sand shaping machine for secondary shaping, after reshaping the composite conditions of the material through the vibrating screen to screen out the finished product.

The construction waste crushing station is different from all kinds of fixed crushing production lines in the past, which has the outstanding advantages of perfect performance, high crushing efficiency and high intelligence, and the mobile crushing station does not need to be driven and fixed, and where it goes is the crushing production site, which is very convenient and reliable to use, and meets the needs of my crushing construction waste.