Popular searched products:

Product Description

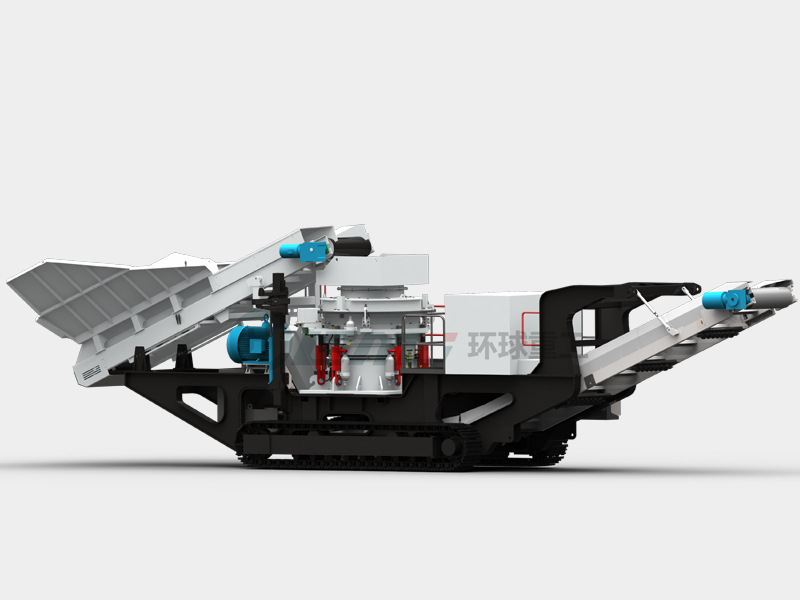

The integrated modular crushing and screening station is a diversified integrated system solution that integrates one or more crushing and screening unit modules according to project requirements.

Its compact structural design saves space and reduces the floor space of the construction site.

The foundation treatment is simple and the equipment foundation is small, avoiding the difficulties of civil construction.

All modules are pre-installed and assembled in the factory, shortening the on-site installation time.

The equipment process is coordinated and smooth, the selection and matching degree is high, and the operating efficiency is excellent.

The installation and maintenance process of the equipment is convenient and efficient, ensuring safety.

The modular station is very convenient to dismantle and reinstall, ensuring that the project can be quickly relocated and reassembled according to construction needs.

All standard modules can be loaded in standard containers for sea transportation.

Product Performance

1. The cone crusher module station is mainly used to process ores and rocks of medium hardness and above, and perform medium and fine crushing operations. 2. According to the configuration of different types of cone crushers, the modular equipment base structural parts are all standardized. 3. The structural design of the module station is simple and beautiful, and all independent components are bolted together for easy installation, disassembly and transportation. 4. According to the requirements of the system design process, standardized intermediate silos and feed hopper module units can also be configured. 5. The module station is equipped with ladders, handrails and wrap-around walkways to facilitate inspection and maintenance of various parts of the cone crusher.Working Principle

Rotation of moving cone and fixed cone: The cone crusher drives the moving cone to rotate through the motor, and the power is transmitted through components such as pulleys and drive shafts. The fixed cone remains stationary, while the moving cone rotates in a relatively fixed position. Due to the special geometric shapes of the moving cone and the fixed cone, the width of the crushing chamber gradually decreases from the feed end to the discharge end. When the material is sandwiched between the moving cone and the fixed cone, the rotation of the moving cone causes the material to move continuously, thereby achieving crushing. Movement of materials in the crushing chamber: After the material enters the crushing shell from the feed port, it is subjected to the pressure of the conical head and the fixed cone. The material undergoes multiple impacts, shocks and crushing in the crushing chamber, and finally achieves crushing. When the material enters the gradually narrowing gap width crushing chamber, the friction between the rotation of the moving cone and the material causes the material to move continuously and be finely crushed. Functions of the hydraulic system and lubrication system: The hydraulic system is used to adjust and protect the crusher. The main shaft cylinder is filled with oil or drained through the hydraulic oil pump to move the main shaft up and down, thereby adjusting the outlet size. When unbreakable foreign matter enters the crushing chamber or the machine is overloaded, the hydraulic safety system will start, the main shaft will drop, and the exhaust port will be enlarged to discharge the foreign matter. The hydraulic system is also responsible for lubricating ball bearings, bevel gears and other components to ensure the normal operation of the machine. The application areas of cone crushers include mining crushing, metallurgy, chemical industry, construction, construction waste recycling, sand and gravel production and cement industries. Due to its efficient crushing capacity and low maintenance cost, cone crushers have been widely used in these fields and can meet the needs of different production processes.Technical Parameters

|

Single cylinder |

Model |

Medium Crushrd |

Finely crushed |

||||||

|

MC-G100S |

MC-G200S |

MC-G300S |

MC-G500S |

MC-G100 |

MC-G200 |

MC-G300 |

MC-G500 |

||

|

给料口尺寸(mm) |

250 |

330 |

380 |

560 |

40-150 |

70-210 |

60-260 |

55-300 |

|

|

Tight edge discharge port(mm) |

25-45 |

30-45 |

30-50 |

30-75 |

8-20 |

10-30 |

8-35 |

10-50 |

|

|

Production Capacity(t/h) |

80-120 |

150-200 |

210-350 |

350-1000 |

50-100 |

100-180 |

120-250 |

200-600 |

|

|

Power(kw) |

90 |

160 |

250 |

315 |

90 |

160 |

250 |

315 |

|

|

Main module structure |

Equipment support, maintenance platform, ladder railing, inlet and outlet hopper, intermediate silo (optional)。 |

||||||||

|

Multi-cylinder |

Model |

MC-H300 |

MC-H400 |

MC-H500 |

||||||||||||

|

standard |

standard |

standard |

Short end |

standard |

Short end |

|||||||||||

|

Cavity Type |

Fine/Medium/Coarse |

Fine/Medium/Coarse |

Fine/Medium/Coarse |

Fine/Medium/Coarse |

Fine/Medium/Coarse |

Fine/Medium/Coarse |

||||||||||

|

Maximum feed size(mm) |

108/169/200 |

70/96/124 |

122/160/264 |

80/106/135 |

144/184/255 |

88/124/152 |

||||||||||

|

Minimum discharge opening(mm) |

16/20/26 |

8/12/14 |

16/22/26 |

8/10/12 |

19/25/25 |

8/10/13 |

||||||||||

|

Capacity(t/h) |

granularity(mm) |

6 |

8 |

10 |

13 |

16 |

19 |

22 |

25 |

32 |

38 |

45 |

51 |

|||

|

MCH-300 |

75-95 |

100- |

110-140 |

145-180 |

170- |

190- |

220-260 |

225-275 |

245- |

300- |

345-430 |

|||||

|

MCH-400 |

105- |

135-170 |

180-225 |

215- |

250- |

275-345 |

285-365 |

315- |

350- |

400-540 |

455- |

|||||

|

MCH-500 |

135- |

170-220 |

225-290 |

270- |

310- |

340-425 |

360-450 |

400- |

425- |

500-670 |

560- |

|||||

|

功率(kw) |

220 |

315 |

400 |

|||||||||||||

|

Main module structure |

Equipment support, maintenance platform, ladder railing, inlet and outlet hopper, intermediate silo (optional). |

|||||||||||||||