Popular searched products:

Product Description

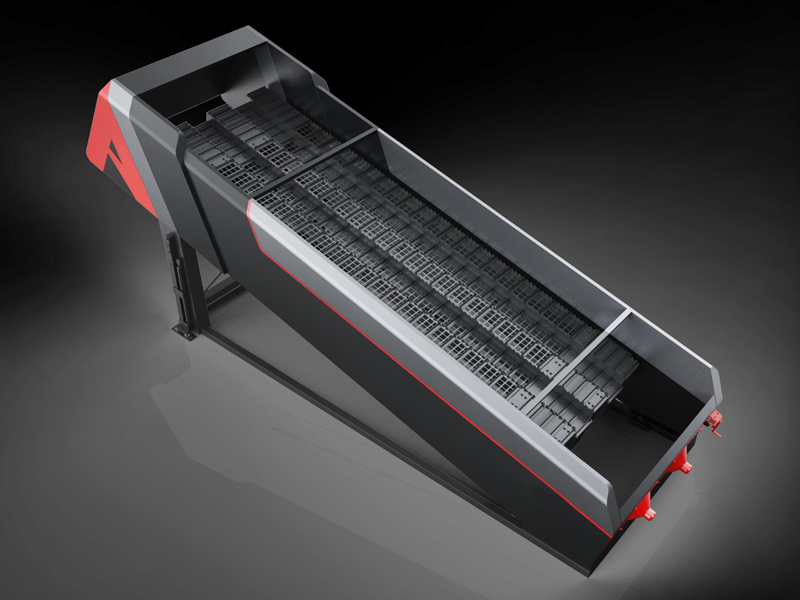

The bouncing screen is a shutdown device with separation function designed for the separation of inorganic particles in the garbage after rough crushing. The machine is to use the characteristics of broken garbage materials, when the garbage reaches a certain particle size, according to the different proportion of materials for sorting operations. The garbage bounce sorting machine is designed with the bounce function to separate inorganic particles or other hard particles while conveying materials on one side, and the separated particles move in the opposite direction with the conveying materials to achieve the purpose of sorting.

Product Performance

- 1Processing power efficiency

The bouncing screen technology can screen different types of garbage quickly and efficiently, and can reduce the labor cost of garbage sorting.

- 2High precision

The screening precision of the bouncing screen technology is high, and it can effectively separate different sizes of garbage particles, so as to obtain better classification effect.

- 3Clean and environmental protection

The materials used in the treatment of domestic waste are not easy to fly, and will not produce dust pollution, so it has better environmental protection characteristics.

- 4Safe and reliable

The operation of the bouncing screen technology is simple and convenient, and the screening process is relatively stable, so it is safer and more reliable than other screening technologies.

Working Principle

Under the action of the drive motor, the spring screen is an equal four-bar machine formed by connecting the main passive transmission mechanism of the drive shaft, passive shaft and eccentric wheel with the support seat and the screen plate. The screen plate produces reciprocating circular motion similar to the spring, and separates three kinds of materials input from the feed port, with large particle size and good rebound effect, heavy and rolling 3D materials. The underscreen materials with small particle size and poor rebound effect, and the flat and lightweight 2D materials with large particle size and poor rebound effect are respectively received by the three discharge bins.

According to the different climbing ability and bounce performance of different materials, the tilt Angle will be affected in the screening process, so the Angle of the spring lifting Angle of the sorted materials can be adjusted by the hydraulic jacking system as a whole.

Note: In order to avoid damage to the screen plate, the size and weight of the feed should be controlled to avoid affecting the sorting effect.

The bouncing sorting screen can not be used for the sorting of large masonry construction waste and large solid waste, such materials need to be picked out before sorting;

The spring sorting screen can not be used for the sorting of strong acid and strong alkaline materials.

Technical Parameters

| Model | EBS-6327 | EBS-6355 |

| Power | 11KW | 22KW |

| Ramp length | 6300mm | 6300mm |

| Ramp width | 340mm | 340mm |

| Number of springboards | 8 | 16 |

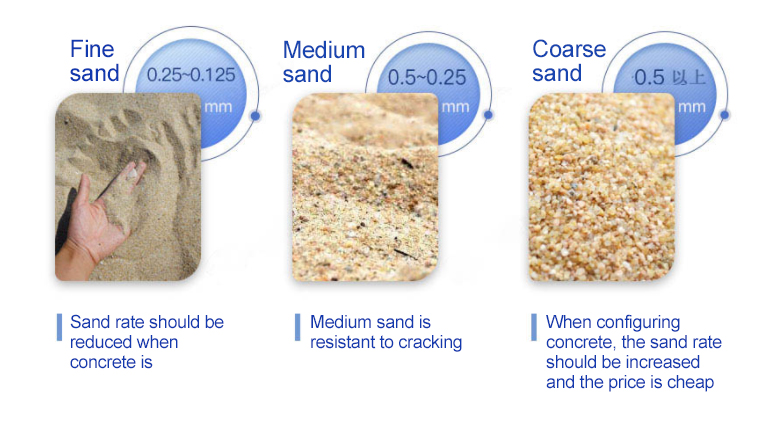

| Springboard screen size | 8-50mm | 8-50mm |

| Device profile | 8500/3900/4800mm | 8500/11200/4800mm |

| Equipment weight | 14ton | 20ton |