Popular searched products:

Product Description

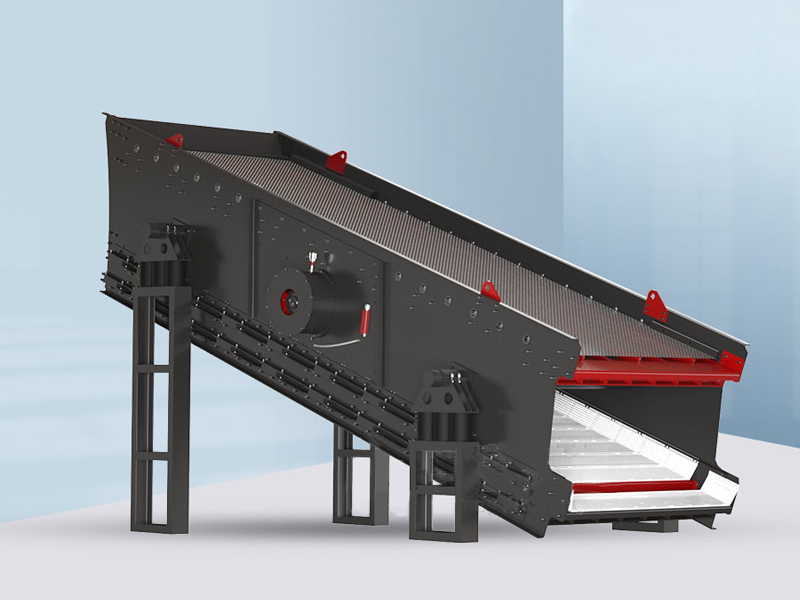

Flashover screen is a kind of equipment used for screening fine, sticky, wet (such as viscous high moisture raw coal and coke of medium and fine particle size classification) and other difficult to screen materials, its design principle is by a single drive to produce double vibration, that is, through resonance, by a driver to provide two vibrations: linear vibration driven by the exciter fixed frame and vibration generated by the floating screen frame. The two move relative to each other. Especially in the case that the material being processed is prone to clogging the screen, the relaxation screen can achieve very high screening efficiency with a relatively small screen area and ensure that the screen is not clogging. Widely used in coal, electric power, coal chemical industry, metallurgy, building materials and other industries.

Product Performance

- 1Dynamic relaxation sieve plate

The screen with relaxation movement has an acceleration beyond the traditional screen machine, which effectively prevents blocking and bonding, and has a strong self-cleaning effect. It is especially suitable for fine screening of difficult sieving.

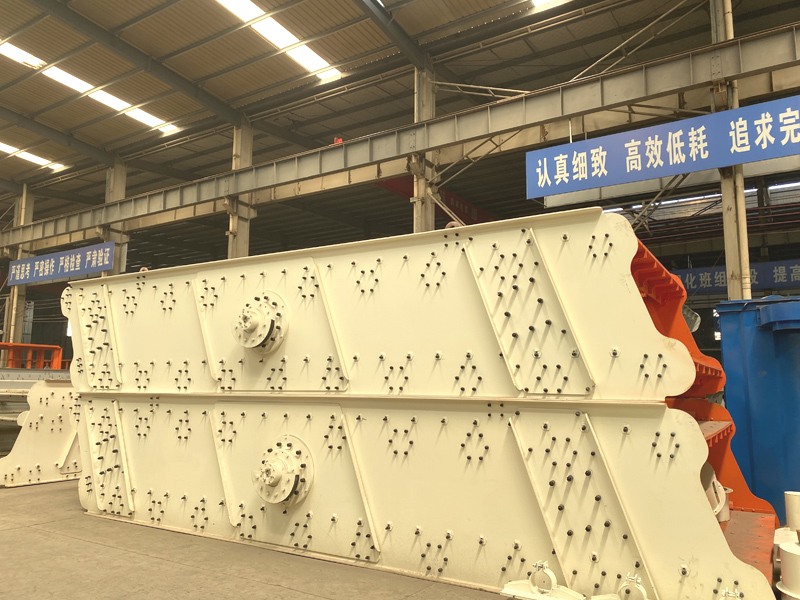

- 2Modular structure design

The screen is fixed without screws, and the quick-disassembly design can quickly disassemble the structural parts on site, which is convenient for maintenance and replacement and flexible adjustment according to the production line. Improve vibration fatigue life and overall reliability. The finite element method makes the structure design more reasonable, avoids resonance and has better stability.

- 3Easy to adjust start and stop

The vibration parameters can be adjusted quickly on site according to the material characteristics. Minimize start-stop jitter and reduce the instantaneous impact on the screen and foundation. At the same time limit the motor starting current, reduce the power supply pressure of the plant.

- 4Optional multi-layer design

According to the actual screening requirements, double-layer or even multi-layer relaxation screen can be customized to achieve a variety of particle size classification.

Working Principle

The relaxation vibrating screen is developed from the traditional circular vibrating screen, using the double vibration principle of basic vibration and additional vibration, the basic vibration is the circular vibration generated by the rotation of the eccentric block, and the additional vibration is the oval vibration driven by the basic vibration. The two reference masses vibrate relative to each other at the same frequency. Because the two ends of the surface are respectively installed on the fixed frame and the floating frame, the polyurethane screen surface continuously expands and contracts, thereby obtaining higher acceleration. The relative linear motion of the two reference masses is adjustable, and all necessary parameters can be adjusted according to the different components. The linear vibrating fixed screen frame and the excited floating screen frame form a resonance system, and the two produce relative motion.

Technical Parameters

| Model | Power(kw) |

| F5YK1540-2P | 11 |

| F5YK1548-2P | 11 |

| F5YK1848-2P | 5.5 |

| F5YK1860-2P | 15 |

| F5YK2148-2P | 18.5 |

| F5YK2160-2P | 22 |

| F5YK2460-1P | 22 |

| F5YK2460-2P | 30 |

| F5YK3060-1P | 30 |

| F5YK3060-2P | 30 |