Popular searched products:

Product Description

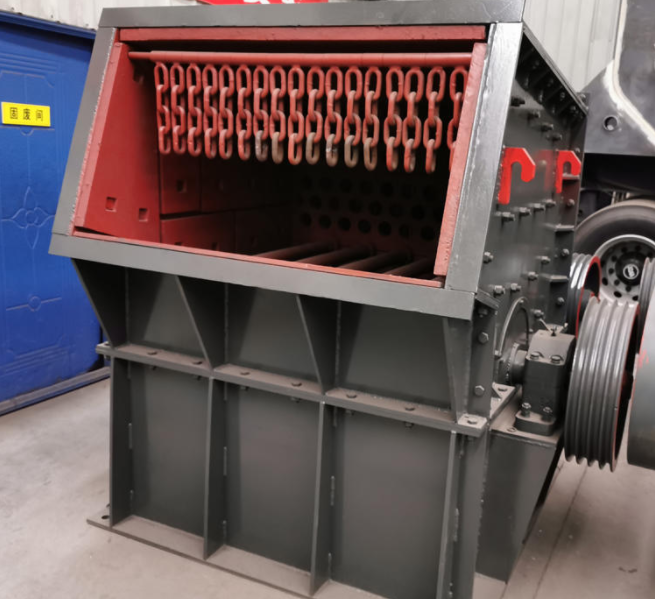

Limestone crusher, also known as jaw crusher and jaw crusher, commonly known as tiger mouth and jaw crusher, occupies the dominant position in crushing equipment. It is mainly suitable for all kinds of ores and large materials. The leader in the crushing production line carries out coarse and medium crushing operations, with stable operation, large crushing ratio, green environmental protection, and low energy consumption. , long service life and other advantages, so the scope of application has been opened, and the field has also expanded from a single mine to many departments such as building materials, highways, railways, water conservancy and chemical industries.

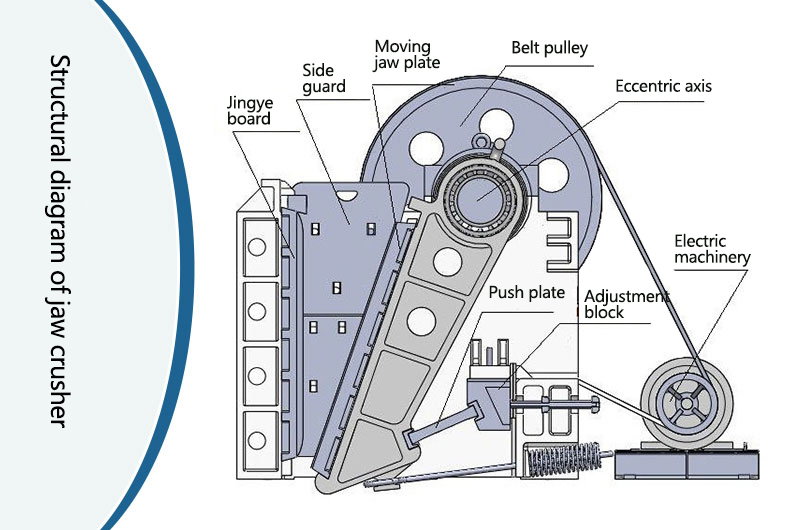

The limestone crusher consists of rack, foot bolt, foundation, moving jaw, elbow plate, elbow plate cushion block, adjustment seat, reserved hole, spring pull rod, adjustment cushion plate, adjustment top wire, support seat, motor slide rail, motor, motor wheel, belt, bearing belt, weight matching block, belt wheel, protective plate, transmission shaft, tension increaser, weight wheel and other components.

Product Performance

- 1Steel frame base, stable operation

The integrated structure of the motor base and the mainframe is convenient to install and save space; the whole machine is installed on the base of the steel frame, with shock-absorbing pads for more stable operation.

- 2Strong crushing ability and high operation efficiency

"V" type crushing cavity, the crushing cavity is deep without dead zone, the movement parameters are optimized, the upper part of the crushing cavity begins to break, the crushing ratio is large, and the production efficiency is high.

- 3High wear-resistant plate, strong and durable

The jaw plate is made of high manganese steel, high ferrochrome and other compressive and wear-resistant materials, which reduce wear and prolong the service life.

- 4Wedge block or hydraulic discharge device, easy to adjust

The wedges are used to adjust the discharge port, which is convenient and fast to adjust and saves manpower. You can also install a hydraulic adjustment outlet device according to your needs to automatically adjust more intelligently.

- 5Strong sealing, production and environmental protection

The broken cavity is strictly sealed to avoid dust leakage, and a dust removal and noise reduction system is installed to further reduce dust pollution and control the noise.

Working Principle

The motor drives the belt and belt wheel, and moves the moving jaw up and down through the eccentric axis. When the moving jaw rises, the angle between the elbow plate and the moving jaw becomes larger, thus pushing the moving jaw plate to approach the fixed jaw plate. At the same time, the material is crushed or broken to achieve the purpose of breaking. When the jaw goes down, the angle between the elbow plate and the moving jaw becomes smaller, and the moving jaw plate leaves the fixed jaw plate under the action of a pull rod and spring. At this time, the broken material is discharged from the lower mouth of the crushing cavity. With the continuous rotation of the motor and crushing and excrete the motor jaw to achieve mass production. When the Red Star manufacturer manufactures equipment, the moving jaw lining plate and fixed jaw lining plate are made of wear-resistant high manganese steel, the main bearing lining tile and eccentric bearing lining tile are made of poured pasteurized alloy, and the elbow plate is made of cast iron to improve its durability and reduce downtime.

Technical Parameters

| Model | Feed size(mm) | Dimension of discharge(mm) | Processing ability(t/h) | lectric motor power(kw) | Appearance and size(mm) |

| PE150×250 | ≤130 | 15-45 | 1-4 | 5.5 | 896×745×935 |

| PE250×300 | ≤150 | 15-55 | 3-6 | 7.5 | 1050×987×1000 |

| PE250×400 | ≤210 | 25-60 | 5-20 | 15 | 1215×1520×1030 |

| PE400×600 | ≤350 | 40-90 | 15-60 | 30 | 1650×1588×1050 |

| PE500×750 | ≤425 | 50-100 | 40-110 | 45 | 1956×1918×1920 |

| PE600×900 | ≤500 | 60-125 | 90-180 | 55 | 2250×2733×2280 |

| PE800×900 | ≤600 | 80-140 | 100-220 | 75 | 2450×2950×2490 |

| PE750×1060 | ≤630 | 60-150 | 110-380 | 110 | 2531×2455×2783 |

| PE900×1060 | ≤700 | 100-160 | 230-390 | 110 | 2900×2657×2950 |

| PE900×1200 | ≤750 | 110-165 | 220-450 | 132 | 3100×2760×3260 |

| PE1000X1200 | ≤900 | 110-185 | 315-500 | 132 | 3200×2760×3260 |

| PE1200×1500 | ≤950 | 115-195 | 550-1000 | 220 | 3710×3446×4075 |

| PE1500×1800 | ≤1200 | 135-225 | 600-1200 | 280 | 5100×4700×4300 |

| PEX150×750 | ≤120 | 10-40 | 8-25 | 15 | 1310×1118×1145 |

| PEX250×750 | ≤210 | 15-50 | 15-35 | 22 | 1400×1751×1515 |

| PEX350×750 | ≤300 | 15-50 | 18-40 | 30 | 1485×1680×1648 |

| PEX250×1000 | ≤210 | 15-60 | 15-60 | 30 | 1550×1964×1380 |

| PEX250×1200 | ≤210 | 15-60 | 20-60 | 37 | 1530×1946×1380 |

| PEX300×1300 | ≤250 | 25-60 | 16-105 | 55-75 | 2000×2320×1730 |