Popular searched products:

Product Description

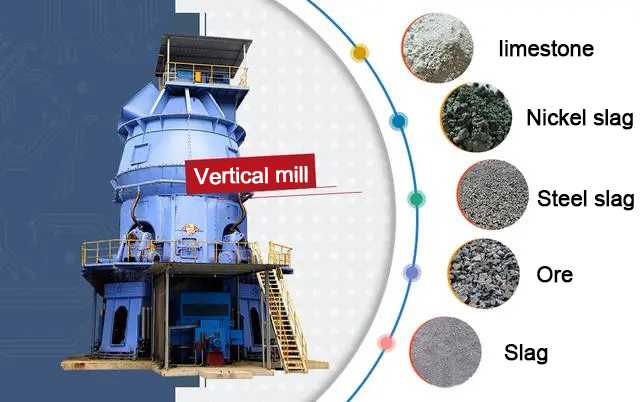

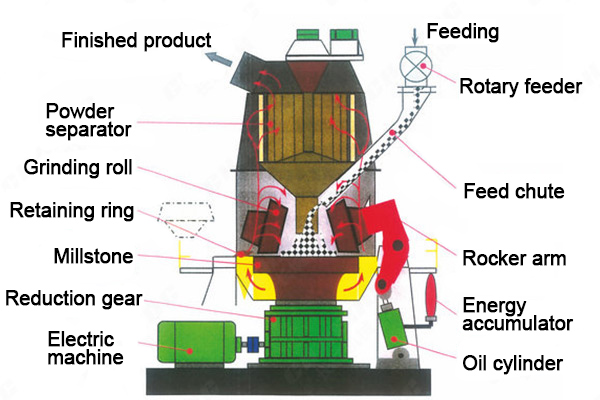

Vertical mill is an ideal large-scale grinding equipment, widely used in cement, electric power, metallurgy, chemical industry, non-metallic minerals and other industries. It integrates crushing, drying, grinding and grading conveying, with high production efficiency. It can grind block, granular and powdery raw materials into the required powdery materials. Vertical mill consists of separator, grinding roller, grinding disc, pressurizing device, reducer, motor, shell, etc.

Product Performance

- 1Clean and environmentally friendly

The entire system operates under complete negative pressure, with reliable sealing, no dust spillage, and a clean environment. Bag-type dust collection is used for finished product collection. The dust removal efficiency is high, which is higher than the environmental protection standard. At the same time, the limit device ensures that the grinding disc and the grinding roller do not come into contact during the working process, with small vibration and low noise.

- 2High production and energy saving

High grinding efficiency, low energy consumption, reasonable roller disc structure design, long grinding curve, large grinding area, grinding roller There is no direct contact with the grinding plate, so the roller sleeve and liner wear less, and the roller sleeve can be turned over, doubling the service life. It is equipped with a hydraulic loading system, which can flexibly adjust the grinding pressure according to changes in grindability, resulting in high production and energy saving.

- 3High degree of automation

Adopt fully automatic control system to realize remote control, simple and convenient, external independent thin oil lubrication station to facilitate oil replacement , the hydraulic maintenance device can easily turn the grinding roller out of the machine, making the replacement of the grinding roller sleeve and the grinding roller maintenance convenient and quick.

- 4The quality of the finished product is stable and reliable

Using a dynamic environmentally friendly powder separator with concentrated particle size distribution, good particle shape, variable frequency speed regulation, and easy adjustment of product fineness , the finished products are selected in time during grinding, which reduces the residence time and number of cycles in the material mill. The finished products have less pollution and high quality.

- 5Low overall cost

While grinding the powder, it has a drying function and can vent hot air to fully mix with the powdery materials directly and multiple times in the grinding mill. Contact drying saves a set of drying equipment and can meet the drying requirements of materials with different humidity by adjusting the hot air temperature.

Working Principle

During the powder production process, the main motor drives the grinding plate to rotate through the reducer. At the same time, hot air enters the vertical mill body from the air inlet. The material falls to the center of the grinding plate through the discharge pipe. The constant-speed rotating grinding plate relies on centrifugal force. The function evenly disperses and spreads the raw materials outward to form a material bed with a certain thickness. The materials are simultaneously crushed by multiple grinding rollers on the grinding disc and crushed. The material continues to move towards the outer edge of the grinding plate under the continuous force of centrifugal force. When the material leaving the grinding plate encounters the hot gas entering the mill through the air ring and rises, it enters the separator through the middle shell of the mill. During this process There is sufficient heat exchange between the medium material and the hot gas, and the water is quickly evaporated. The powder selector controls the particle size of the finished product at the exit of the roller mill. Particles larger than the specified size are separated and fall back to the grinding plate. Materials that meet the fineness requirements enter the dust collector through the powder selector, and the collected finished products are sent to the finished product warehouse.

Technical Parameters

| Model | Output (t/h) | Grinding disc geometric diameter (mm) | Grinding disc track diameter (mm) | Raw material moisture (%) | Raw meal fineness (%) | Raw meal moisture (%) | Main motor power (kW) | < /tr>

| ZKRM1300 | 20-25 | 1870 | 1300 | <10% | R0.08≤12% | ≤1% | 200 |

| ZKRM1500 | 26-34 | 2180 | 1500 | <10% | R0.08≤12% | ≤1% | 280 |

| ZKRM1700 | 40-50 | 2400 | 1700 | <10% | R0.08<12% | ≤1% | 400 |

| ZKRM1900 | 60-70 | 2680 | 1900 | <10% | R0.08<12% | ≤1% | 500 |

| ZKRM2200 | 85-110 | 2900 | 2200 | <10% | R0.08<14% | ≤1% | 800 |

| ZKRM2400 | 95-130 | 3140 | 2400 | <10% | R0.08<14% | ≤1% | 900 |

| ZKRM2800 | 120-160 | 3300 | 2800 | <10% | R0.08<14% | ≤1% | 1250 |

| ZKRM3400 | 190-240 | 4560 | 3400 | <10% | R0.08<15% | ≤1% | 1800 |