Popular searched products:

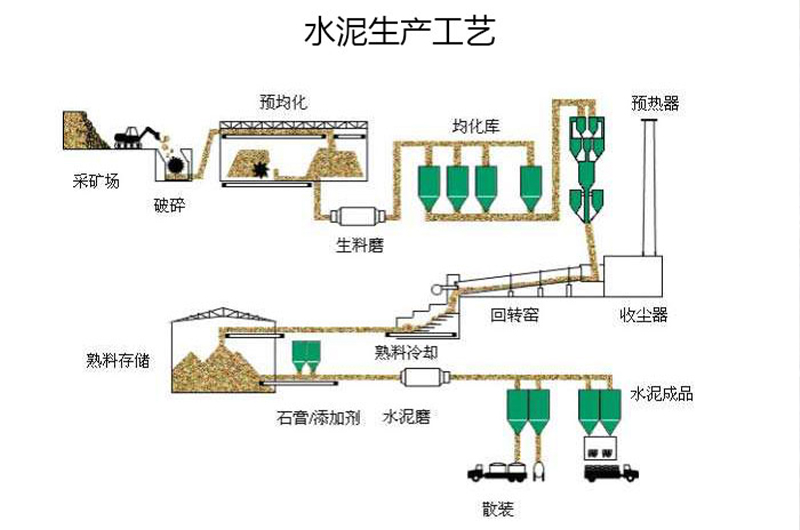

Cement can be seen everywhere in our lives. Cement is needed to build houses, bridges, pave roads, etc. The cement production method is very complicated, including: crushing and pre-homogenization, raw meal preparation, raw meal homogenization, preheating and decomposition, clinker burning, grinding and other processes.

Cement production methods and processes:

1. Crushing and pre-homogenization

(1) Crushing In the cement production process, most raw materials need to be crushed, such as limestone, clay, iron ore and coal. Limestone is the largest raw material used in cement production. After mining, the particle size is larger and the hardness is higher. Therefore, limestone crushing plays an important role in material crushing in cement plants.

(2) Pre-homogenization of raw materials Pre-homogenization technology is to use scientific stacking and retrieval technology to achieve preliminary homogenization of raw materials during the storage and retrieval process of raw materials, so that the raw material yard has the functions of storage and homogenization at the same time.

2. Preparation of raw materials

In the cement production process, at least 3 tons of materials (including various raw materials, fuels, clinkers, mixtures, and gypsum) must be ground for every ton of Portland cement produced. According to statistics, the dry cement production line grinding operation consumes Power accounts for more than 60% of the power of the whole plant, of which raw material grinding accounts for more than 30%, coal grinding accounts for about 3%, and cement grinding accounts for about 40%. Therefore, rational selection of grinding equipment and process flow, optimization of process parameters, correct operation, and control of operating systems are of great significance to ensuring product quality and reducing energy consumption.

3. Homogenization of raw materials

In the new dry process cement production process, stabilizing the composition of the raw meal entering the pit is the prerequisite for stabilizing the thermal system of clinker firing. The raw meal homogenization system plays the final check role in stabilizing the composition of the raw meal entering the pit.

4. Preheating and decomposition

The preheating and partial decomposition of the raw meal is completed by the preheater, replacing part of the function of the rotary kiln to shorten the length of the return kiln. At the same time, the heat exchange process of gas and material is carried out in the piled state in the kiln, and moved to the suspended state inside the preheater. It is carried out at a lower speed, so that the raw material can be fully mixed with the hot gas discharged from the kiln, which increases the contact area of the gas and material, the heat transfer speed is fast, and the heat exchange efficiency is high, thereby improving the production efficiency of the kiln system and reducing the heat consumption of clinker firing. Purpose.

(1) Material dispersion

80% of the heat exchange is carried out in the inlet pipe. The raw material fed into the preheater pipe is impacted by the high-speed upward airflow, and the material turns upward and moves with the airflow, and is dispersed at the same time.

(2) Gas-solid separation

When the airflow carries the powder into the cyclone, it is forced to rotate in the annular space between the cyclone cylinder and the inner cylinder (exhaust pipe), and moves downward while rotating, from the cylinder to the cone. , can extend to the end of the cone, then turn upward to rotate and rise, and be discharged from the exhaust pipe.

(3) Pre-decomposition

The emergence of pre-decomposition technology is a technological leap in the cement calcination process. It adds a decomposition furnace between the preheater and the rotary kiln, uses the rising flue at the end of the kiln, and sets up a fuel injection device to combine the exothermic process of fuel combustion with the endothermic process of carbonate decomposition of raw materials. The process is carried out rapidly in the furnace in a suspended or fluidized state, which increases the decomposition rate of raw materials entering the kiln to more than 90%. The carbonate decomposition task originally carried out in the rotary kiln is moved to the decomposition furnace; most of the fuel is added from the decomposition furnace, and a small part is added from the kiln head, which reduces the heat load of the calcining zone in the kiln and extends the lining The life of the material is long, which is conducive to large-scale production; because the fuel and raw material are evenly mixed, the fuel combustion heat is transferred to the material in time, so that the combustion, heat exchange and carbonate decomposition processes are optimized. Therefore, it has a series of excellent performances and characteristics such as high quality, high efficiency and low consumption.

5. Burning of cement clinker

After the raw meal is preheated and pre-decomposed in the cyclone preheater, the next process is to enter the rotary kiln for clinker firing.

In the rotary kiln, the carbonate further rapidly decomposes and undergoes a series of solid phase reactions to generate minerals in cement clinker. As the temperature of the material increases, the minerals will turn into a liquid phase, and the dissolved minerals in the liquid phase will react to form a large amount of (clinker). After the clinker is fired, the temperature begins to decrease. Finally, the cement clinker cooler cools the high-temperature clinker discharged from the rotary kiln to a temperature that can be tolerated by downstream transportation, storage and cement mills. At the same time, the sensible heat of high-temperature clinker is recovered to improve the thermal efficiency of the system and clinker quality.

6. Cement grinding

Cement grinding is the final process of cement manufacturing and the process that consumes the most electricity. Its main function is to grind cement clinker (and gelling agent, performance adjustment materials, etc.) to the appropriate particle size (expressed in terms of fineness, specific surface area, etc.) to form a certain particle gradation and increase its hydration area. Accelerate the hydration rate and meet the cement slurry setting and hardening requirements.

7. Cement packaging

Cement is shipped from the factory in two ways: bagged and bulk.

Related Reading

- What is machine-made sand? Why is machine-made sand so popular? What are the advantages of machine-made sand?

- Regarding the price of mobile sand making machines, manufacturer recommendations, and sand blasting effects, this article has everything you want to know!

- To improve the sand and gravel technology, save energy and increase efficiency, and improve the quality of sand production, you should read this article carefully!

- I heard that the profit of machine-made sand washing is good, how much is it? Which equipment is suitable for machine-made sand washing?

- If you want to choose a cost-effective truck-mounted mobile sand washing machine, Zhengzhou Global Heavy Industry is your first choice

- If you want to make sand washing production and processing more flexible, mobile sand washing station is your first choice!

Product show

Product

Source:

Source: Time:2024/04/26 14:03:03

Time:2024/04/26 14:03:03