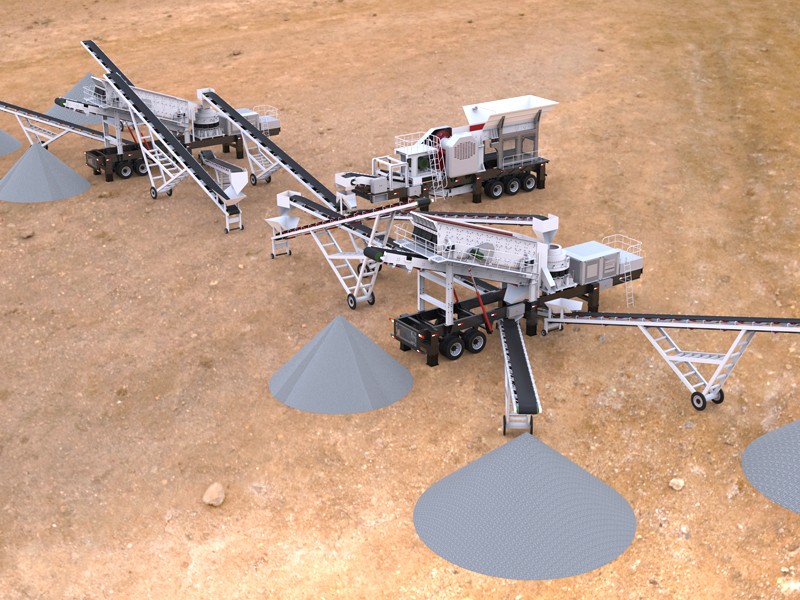

Production line of 200 tons of mobile crushing station

Production Capacity:200t/h

Processing materials:Granite, diabase, basalt, limestone, river pebble, iron ore, copper ore, dolomite, rhyolite, manganese ore, phosphate ore

Power Consumption:

Production Capacity:200t/h

Processing materials:Granite, diabase, basalt, limestone, river pebble, iron ore, copper ore, dolomite, rhyolite, manganese ore, phosphate ore

Power Consumption:

Global Heavy industry quality is good

Applicable materials: granite, diabase, basalt, limestone, river pebbles, iron ore, copper ore, dolomite, rhyolite, manganese ore, phosphate ore

Application fields: mine crushing, sand and stone yard, road, railway, construction and other fields

Equipment configuration: Tire cone mobile crushing station, tire jaw mobile crushing station

In March 2022, Xinjiang customers purchased Global Heavy Industry's tire cone mobile crushing station, tire Jaw mobile crushing station and other mobile crushing equipment, using granite as raw materials to produce 0-2 mm, 12-20 mm and 30-40 mm aggregate, the finished sand has uniform particle size and high compressive strength, which is far more in line with the construction requirements than natural sand. The economic benefits are considerable.

Integrated unit

The integrated unit equipment installation mode eliminates the complex site infrastructure and auxiliary facilities installation operations of separate components, and reduces the consumption of materials and working hours. The reasonable and compact space layout of the unit optimizes the space of the facility configuration in the site to the maximum extent. The facility layout is simple and compact, and the space for material stacking and transfer is expanded.

Flexible

The wheeled series mobile crushing station has high vehicle site and small turning radius, which is convenient for ordinary road driving and more convenient for driving in the rough and harsh road environment of the crushing site. Saves time for quick site entry. It is more conducive to entering the reasonable construction area, and provides a more flexible working space for the overall crushing process.

Reduced material handling costs

The wheeled series mobile crushing station can crush the material at the first line, eliminating the intermediate link of the material being transported away from the site and then crushed, and greatly reducing the transportation cost of the material. In addition, the extended unit is more able to directly feed the broken material into the specific transfer belt conveyor.

Job function is direct and effective

Integrated tire series mobile crushing station, can be used independently, but also for customers in the process of material type, product requirements, to provide more flexible process plan configuration, to meet the user's mobile crushing, mobile screening and other requirements, so that the generation of organization, logistics transport more direct and effective, the cost to maximize the reduction.

Flexible configuration

The wheeled series mobile crushing station provides customers with a simple and low-cost characteristic combination unit configuration. For coarse crushing and fine crushing screening system, a single unit can be operated independently, or a flexible system can be configured for joint operation. The hopper side outlet provides flexibility for various configurations of the screening material conveying method. The diesel generator in the integrated unit configuration can not only supply power to the unit, but also configure the unit joint power supply to the process system.

Reliable performance and easy maintenance

Wheeled series mobile crushing station, can be configured with various series of crusher, high crushing efficiency, versatility, excellent crushing product quality, with lightweight and reasonable structure design, excellent crushing performance. Reliable and stable quality assurance, to meet the maximum range of coarse, medium and fine material crushing and screening requirements, for the majority of new and old customers at home and abroad to establish a good quality reputation, not only mature technology, easy to operate and maintain, but also for the transport volume, material size and abrasive properties have good adaptability and safety and reliability, integrated unit configuration, installation and maintenance convenient and reasonable.

The stone material is sent to the tire jaw breaking mobile crushing station for coarse crushing, and the finished product after coarse crushing is directly transported to the crushing chamber of the tire cone breaking mobile crushing station by the conveyor belt, and then screened by the vibrating screen, the finished product qualified for screening is transported by the conveyor belt to the tire screening station for fine screening, and the unqualified material on the screen is transported by another conveyor belt to the coarse crushing machine for re-crushing. The production line can operate independently, saving labor management costs.

The set of stone processing equipment configured by Global Heavy Industry for our company, the output can be flexibly adjusted, the operation efficiency is relatively high, the energy consumption is low, the river pebble, granite, basalt and other materials have a very good processing effect, greatly improve its comprehensive recovery rate, easy to operate, the response in the production workshop is very good, and the benefit is also high.