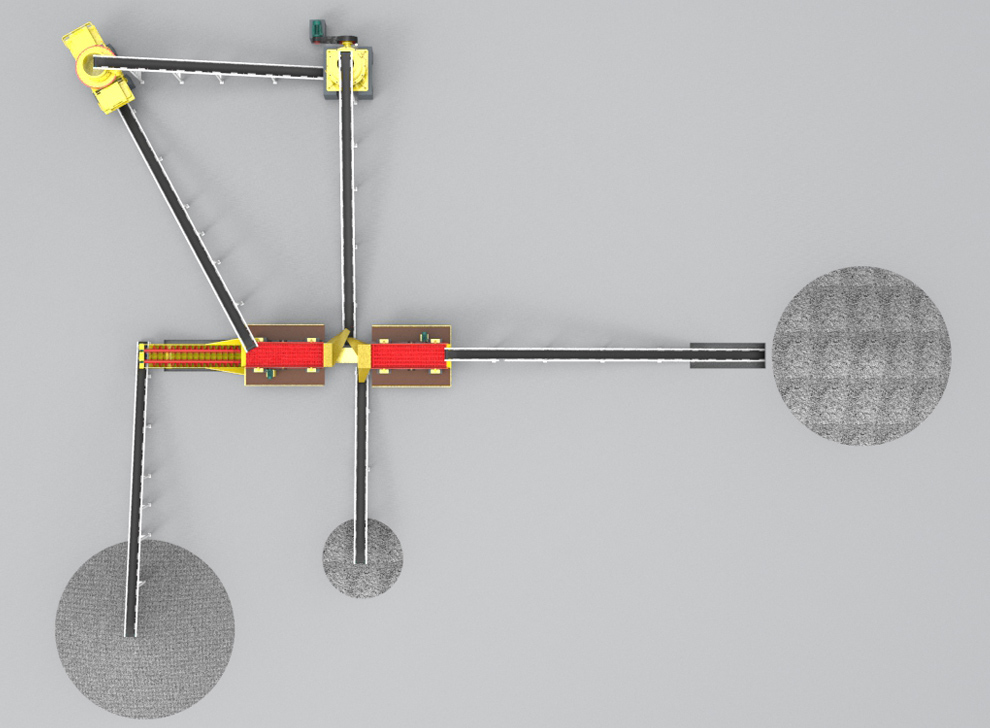

Sea sand control production line

Production Capacity:100-300t/h

Processing materials:Quartz stone, limestone, basaltic stone, granite, pebbles and other rocks

Power Consumption:

Production Capacity:100-300t/h

Processing materials:Quartz stone, limestone, basaltic stone, granite, pebbles and other rocks

Power Consumption:

Global Heavy industry quality is good

Cone crusher sand production line is suitable for hydropower, building materials, highways, urban construction and other industries, can be used for hard limestone, granite, basalt, river pebbles, slag and other materials aggregate and artificial sand making operations, It is especially suitable for the production and processing of expressway surfacing material, high-grade highway pavement gravel, high-speed railway passenger dedicated line gravel aggregate, hydropower station gravel, port wharf and airport runway gravel and other special construction fields.

1, a wide range of applications: This sand production line can not only be used for quartz sand, but also for limestone, basalt, granite, pebbles and other rocks crushing processing.

2, the finished product effect is good: After sand processing, the product is mostly cube-like, low needle flake content, no internal cracks, high compression strength, in line with the mechanical sand standard.

3, high safety factor: The production line is equipped with an alarm device, once the production line occurs bad operation can start the alarm device, so as to achieve the purpose of protecting the equipment.

4, long service life: production line configuration equipment of the wearing parts are made of the current domestic high-strength wear-resistant materials, easy maintenance, small loss, long service life, for customers to bring better economic benefits.

The raw material is sent to the cone crusher for secondary crushing at a uniform speed by the vibrating feeder, the broken material is screened by the vibrating screen, and the material that does not meet the feeding requirements of the sand making machine is returned to the cone crusher for re-crushing, the material that meets the feeding size of the sand making machine is sent to the sand making machine for fine breaking, and the fine broken material is screened by the vibrating screen again. If it does not meet the requirements, it will be returned to the sand making machine for further crushing. If it meets the requirements, it will be sent to the spiral sand washing machine for cleaning. After cleaning, the sand and stone can be dehydrated to get the finished product.