Popular searched products:

Product Description

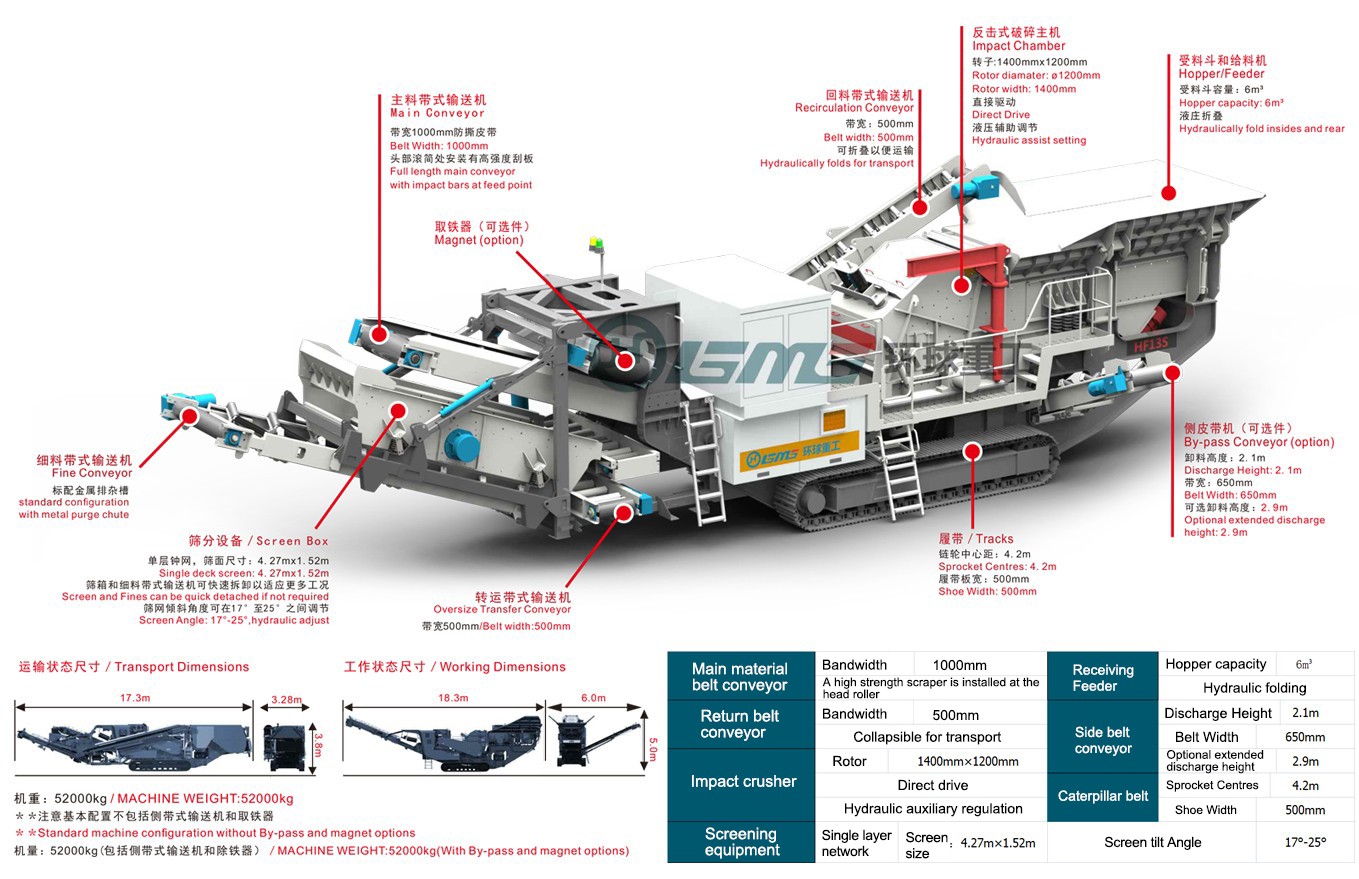

HIR tracked impact crushers provides the versatility of a crushing and screening plant on one machine. Based on the HI the machine features an innovative quick detach 4270mm x1520mm single deck screen for sizing and recirculating oversize material back to the crushing chamber. The sizing screen can be quickly removed for applications that do not require resizing or recirculation of materials for further processing.

Product Performance

Detachable 4270mmx1520mm single deck screen passes oversize material back to the crusher via the on-board recirculating system.

Quick and easy detachable screen and fines conveyor for open circuit crushing.

The onboard fines conveyor has a high discharge height of 3700mm for stockpiling or further processing by a secondary screener

Working Principle

The raw materials are fed into the silo by forklifts, excavators and other equipment, and the materials in the silo enter the screening feeder, where the parts of the raw materials with the required particle size leak from the sieve hole and form the mound directly through the unearthed belt conveyor; The larger material is broken through the screen feeder into the European impact crusher, and then when the particle size reaches the standard, it is discharged from the discharge port into the vibration discharge machine; The discharging machine evenly sends the material to the main discharging belt machine, and the belt machine transports the material out to form a material pile; At the same time, an iron remover is installed above the main discharge belt, and the iron in the material is separated after being drawn by the iron remover.

Technical Parameters

| HI721R | HI731R |

| Chamber | |

| IH1313IMPACTCHAMBER | IH1313IMPACTCHAMBER |

| 4 bar rotor | 4 bar rotor |

| Hydraulically assisted apron setting | Hydraulically assisted apron setting |

| Feeder Hopper | |

| Hopper capacity:6m³ | Hopper capacity:6m³ |

| Hydraulically folding hopper sides | Hydraulically folding hopper sides |

| Heavy duty vibrating feeder | Heavy duty vibrating feeder |

| Stepped grizzly feeder with integral pre-screen, standard 50m n spacing | Stepped grizzly feeder with integral pre-screen, standard 50m n spacing |

| Selectable discharge to by-pass conveyor or main conveyor | Selectable discharge to by-pass conveyor or main conveyor |

| Mesh aperture on grizzly feeder: 38mm | Mesh aperture on grizzly feeder: 38mm |

| Main Conveyor | |

| Belt:1200mm full length | Belt:1200mm full length |

| High spec scraper at head drum | High spec scraper at head drum |

| Recirculation Conveyor | |

| Beltwidth:500mm | Beltwidth:500mm |

| Folding for Transport | Folding for Transport |

| Fines Conveyor | |

| Beltwidth:500mm | Beltwidth:500mm |

| Folding for Transport | Folding for Transport |

| Screen Box | |

| Single Deck Screen:4.27mx1.52m | Single Deck Screen:4.27mx1.52m |

| Quick detach screen and fines for more versatility | Quick detach screen and fines for more versatility |

| Screen angle from 17°to 25 | Screen angle from 17°to 25 |

| Screen 40mm apperture fitted as standard | Screen 40mm apperture fitted as standard |

| Oversize Transfer Conveyor | |

| Beltwidth:500mm | Beltwidth:500mm |

| General | |

| Shower and dust removal system | Shower and dust removal system |

| Piped for overband magnet | Piped for overband magnet |

| Track is soft start with 2 optional speeds | Track is soft start with 2 optional speeds |

| Hand-held remote control with cable can control the track within 5m range | Hand-held remote control with cable can control the track within 5m range |

| Heavy duty undercarriage unit with 500mm shoe width | Heavy duty undercarriage unit with 500mm shoe width |

| Low level greasing points | Low level greasing points |

| Galvanised catwalk c/w handrail, kick board and access ladders | Galvanised catwalk c/w handrail, kick board and access ladders |

| Emergency stops(6 nr) | Emergency stops(6 nr) |