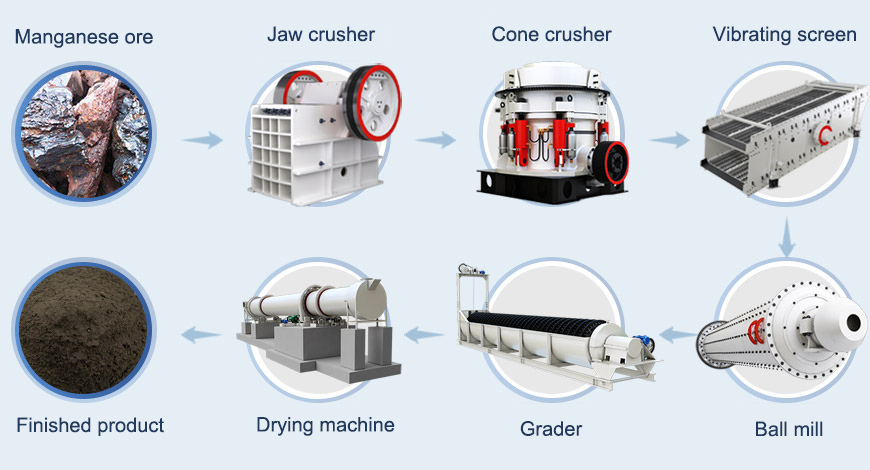

manganese ore beneficiation production site

Production Capacity:0.18-7m3/min

Processing materials:锰矿、铜矿、镍矿、铁矿、金矿等金属矿的浮选

Power Consumption:暂无数据

Production Capacity:0.18-7m3/min

Processing materials:锰矿、铜矿、镍矿、铁矿、金矿等金属矿的浮选

Power Consumption:暂无数据

Global Heavy industry quality is good

Manganese ore is a relatively common mineral resource in nature. There are many types of manganese ore. However, there are only 6 types of pyrolusite, hard manganese ore, hydromanganese ore, and black manganese ore that have good mining value. They are mainly distributed in Guangxi, Guizhou, and Guangdong in my country. , Jiangxi and other places. After processing, manganese ore has a wide range of applications in metallurgy, chemistry, chemical industry, building materials, aerospace, national defense, environmental protection and other fields.

1. The ore utilization rate can reach 90%, and the water consumption during the process is small, which saves cost investment and maximizes profit margins;

2. The dust in the magnetic separation is collected by the dust removal device, which will not cause air pollution. It is a creative process method with high production efficiency, good product quality and no environmental pollution;

3. It has low requirements on the working site environment and can achieve high production and low consumption even if the environment is not good;

4. The entire magnetic separation process has a high degree of automation, which can reduce manual operations.

1, the manganese ore is sent to the jaw crusher by the vibration feeder for initial break, after the initial break is sent to the cone crusher for second break, the second break after the material is screened, the particle size to meet the requirements is sent to the next processing link, the non-requirements are returned to the cone crusher to continue crushing;

2, meet the requirements are sent to the ball mill for grinding, and then sent to the classifier for sorting, particle size unqualified is returned to the ball mill to continue screening, qualified is sent to the next processing link;

3, qualified manganese ore powder is first sent to the mixing tank and medicine for full mixing, and then sent to the classifier for sorting, to obtain manganese metal;

4, after the flotation of manganese metal high water content, choose concentrator and dryer, concentrator will dehydrate manganese metal, dryer will further dry manganese metal, and then get dry manganese metal.

Global Heavy Industry engineers planned and formulated this relatively reasonable and economical production line process design for us based on the environment, geology, and climate. There are fewer wearing parts during use, which is very practical. Half a year after it was put into production, we can still receive goods from Global Heavy Industry. We received a return call from Global Heavy Industry to inquire whether we encountered any problems during use. We are very satisfied with the after-sales service of Global Heavy Industry! Looking forward to our next cooperation!