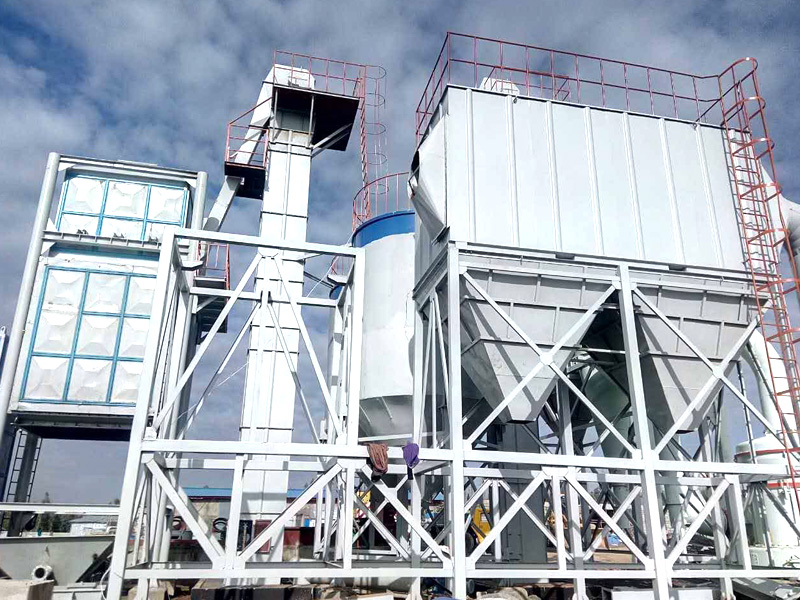

Gypsum powder grinding production line

Production Capacity:4-55t/h

Processing materials:生石膏

Power Consumption:暂无数据

Production Capacity:4-55t/h

Processing materials:生石膏

Power Consumption:暂无数据

Global Heavy industry quality is good

This construction gypsum powder production line is carried out using relatively mature production technology and production equipment. The finished gypsum powder produced can well meet user requirements in terms of powder particle size and finished product purity, and it operates with high output and efficiency. High, which can bring stable long-term benefits to users.

Easy to operate and reliable in operation

Equipped with an automatic control system, it has a high degree of automation, can realize remote control, and is easy to operate.

Energy saving and environmental protection

Provide users with comprehensive solutions for crushing, drying, grinding, screening, packaging design, supply, construction, and services. Equipped with a special dust collector, the dust emission is small and the dust removal effect reaches 99.99%, basically achieving dust-free operation in the workshop; the operating noise is low and the machine vibration is small.

Finished product quality is stable

The crushing ratio is large, the powder extraction rate is high, the particle size of the finished product is uniform, and the quality of the finished product is stable.

Gypsum powder processing is generally divided into gypsum coarse powder processing (0-3MM), fine powder processing (20 mesh-400 mesh), as well as ultra-fine powder deep processing of gypsum (400 mesh-1250 mesh) and micro powder processing (1250 mesh) —3250 mesh) four types.

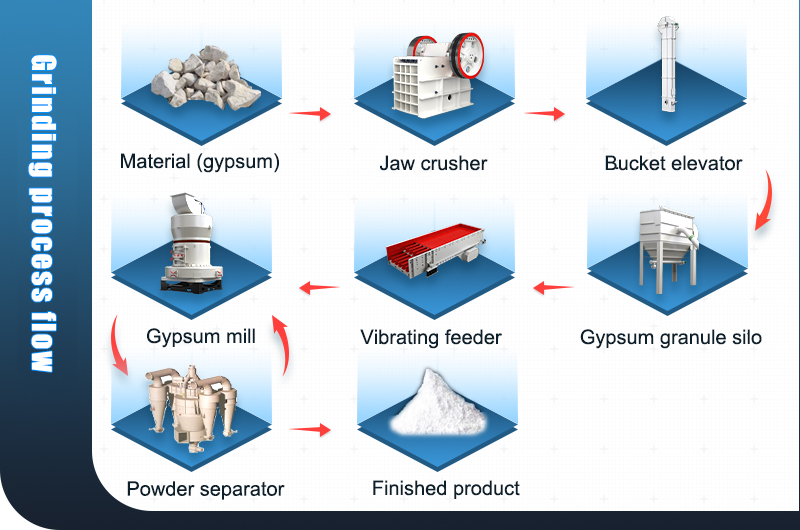

The first stage: broken

The large pieces of gypsum material are crushed by the crusher to the feeding fineness (15mm-50mm) that can enter the grinding mill.

The second stage: grinding

The crushed gypsum small pieces are sent to the silo through the elevator, and then sent to the grinding chamber of the mill uniformly and quantitatively through the vibrating feeder for grinding. Fine powder processing generally uses grinding equipment such as Raymond mill and high-strength grinding mill.

The third stage: grading

The ground gypsum materials are classified by the powder selector. Unqualified powder is classified by the powder selector and returned to the host machine for re-grinding.

The fourth stage: gathering fans

Powder that meets the fineness will enter the dust collector through the airflow through the pipe for separation and collection. The collected finished powder will be sent to the finished product silo through the discharge port through the conveyor device, and then unified into a powder tanker or automatic baling machine. For packaging.

A year ago, I bought a grinding mill from Global Heavy Industries through the introduction of a friend. The performance is very stable. Accessories have long service life and are easy to maintain. Therefore, our company saves hundreds of thousands a year in repair and maintenance costs alone. Therefore, if our company needs equipment, we will choose Global Heavy Industries again